How Does PVC Film Perform in Thermoforming Processes?

Introduction: Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed into a specific shape by applying vacuum or pressure, and then trimmed to create a finished product. PVC film, known for its versatility and durability, is a popular choice for thermoforming applications. This article delves into the performance of PVC film in thermoforming processes, exploring its properties, advantages, and applications.

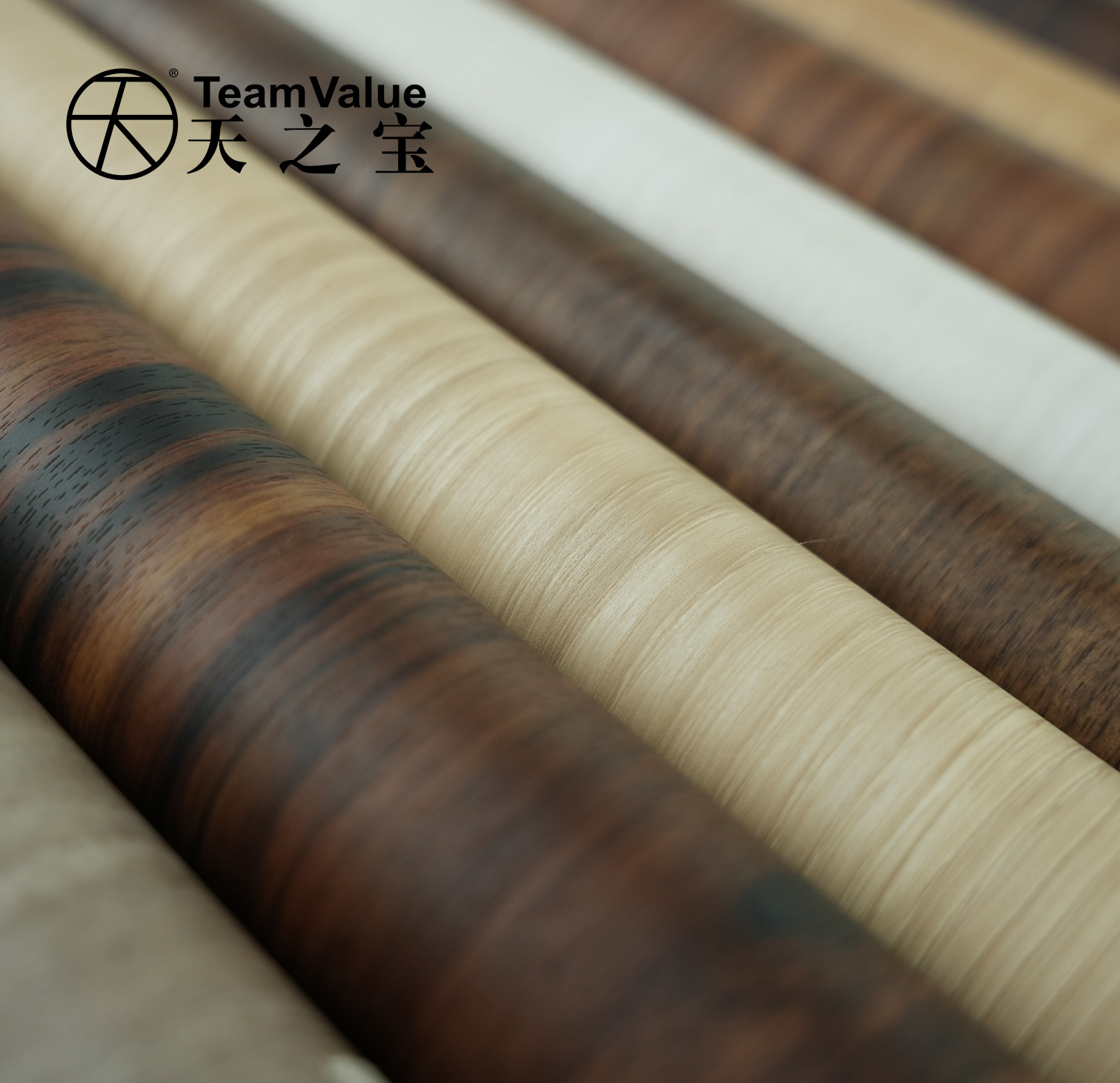

Properties of PVC Film in Thermoforming: PVC film's suitability for thermoforming is attributed to its unique properties. It is a thermoplastic material, meaning it can be heated and reshaped multiple times without losing its properties. The film's flexibility, clarity, and resistance to chemicals and weather make it an ideal choice for various thermoforming applications.

How PVC Film is Prepared for Thermoforming: Before thermoforming, PVC film must be prepared correctly. The film is first cut to the desired size and shape, taking into account the shrinkage that occurs during the heating process. It is then heated to a specific temperature, which makes it pliable and ready for forming. The temperature must be carefully controlled to avoid overheating, which can lead to deformation or degradation of the PVC.

The Thermoforming Process with PVC Film: Once the PVC film is heated, it is placed over a mold and vacuum or pressure is applied to form the film into the mold's shape. The key to a successful thermoform is the ability of the PVC film to conform to the mold's contours without tearing or losing its structural integrity. PVC's flexibility and strength make it well-suited for this process.

Advantages of Using PVC Film in Thermoforming: PVC film offers several advantages in thermoforming. Its clarity allows for high-quality, aesthetically pleasing results. The film's durability ensures that the finished products are long-lasting and resistant to wear. Additionally, PVC is cost-effective, making it an economical choice for manufacturers. The film's resistance to chemicals and weather also makes it suitable for a wide range of applications, from packaging to construction.

![]()

Applications of PVC Film in Thermoforming: PVC film is used in thermoforming for a variety of products, including packaging trays, signage, and automotive components. Its ability to be thermoformed into complex shapes without losing strength makes it a popular choice for these applications. The film can also be printed on before or after the thermoforming process, allowing for customization and branding opportunities.

Conclusion: PVC film's performance in thermoforming processes is a testament to its versatility and durability. Its ability to be heated and reshaped, combined with its resistance to chemicals and weather, makes it a popular choice for a wide range of applications. By understanding the properties of PVC film and the thermoforming process, manufacturers can create high-quality products that meet the demands of their industries.