How Does PVC Film Exhibit Fire Resistance?

Introduction: The Importance of Fire Resistance in Materials

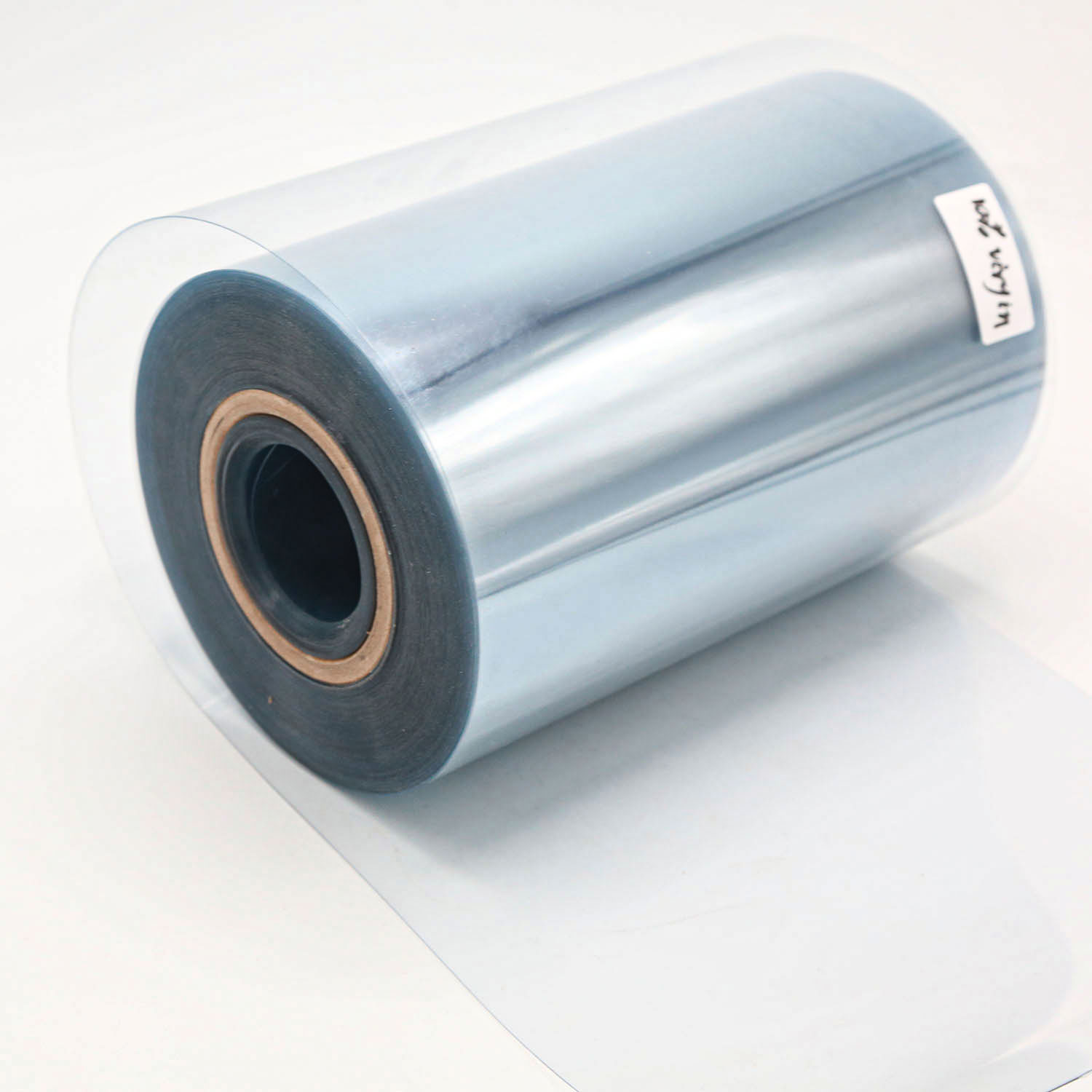

Fire resistance is a crucial attribute for materials used in various applications, particularly in construction and packaging. Polyvinyl Chloride (PVC) film is known for its versatility and durability, but its fire-resistant properties often take center stage in discussions about its applications. This article examines the fire-resistant characteristics of PVC film, the science behind it, and its implications for safety in various industries.

Understanding PVC and Its Fire Resistance Mechanism

PVC is a widely used thermoplastic polymer that exhibits a unique combination of properties, including strength, flexibility, and fire resistance. The fire-resistant qualities of PVC stem from its chemical composition, primarily its chlorine content. When PVC is exposed to high temperatures, it undergoes a process that releases hydrochloric acid. This release of acid helps to inhibit flame spread and reduces the overall intensity of fires, making PVC a self-extinguishing material.

The Role of Additives

Modern advancements in PVC technology have led to the incorporation of various additives that enhance its fire resistance. Flame retardants, for example, can be added to PVC formulations to create a more robust barrier against combustion. These additives work by interfering with the combustion process, effectively slowing down or stopping the spread of flames. As a result, PVC films can meet stringent fire safety regulations, making them suitable for high-risk environments such as construction sites and public buildings.

Applications of Fire-Resistant PVC Films

The fire-resistant properties of PVC films make them ideal for a variety of applications. In the construction industry, PVC films are commonly used as insulation materials, roofing membranes, and window frames. Their ability to resist flames significantly contributes to overall building safety, reducing the risk of fire hazards.

In the automotive sector, fire-resistant PVC films are utilized in interior components, such as dashboard covers and seat upholstery. This not only enhances the aesthetic appeal of vehicles but also serves a critical safety function, minimizing the potential for fire-related accidents.

Performance Under Fire Conditions

Testing has shown that PVC films maintain their structural integrity under high-temperature conditions. Fire tests indicate that PVC films can withstand flames for a limited time without significant degradation, providing valuable time for evacuation and firefighting efforts. This characteristic is particularly important in commercial buildings, where large numbers of people may be present.

Regulatory Compliance

PVC films are designed to meet various fire safety standards. For instance, they must comply with regulations set by organizations such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL). Meeting these standards ensures that PVC films are safe for use in applications where fire risk is a concern.

Conclusion: The Significance of Fire Resistance in PVC Films

The fire-resistant properties of PVC films are essential for ensuring safety across multiple industries. By leveraging their inherent chemical properties and incorporating advanced flame-retardant additives, PVC films provide a reliable solution for applications where fire safety is paramount. As industries continue to prioritize fire safety, the demand for fire-resistant materials like PVC films is expected to grow, reinforcing their role as a critical component in modern manufacturing and construction practices.