How Many Steps It Takes to Produce a Cabinet?

(And Where PVC Film Shines!)

That beautiful new cabinet in your kitchen or living room didn’t just magically appear. It’s the result of a carefully orchestrated process involving numerous steps, skilled craftsmanship, and advanced materials. Ever wondered exactly how many steps it takes and what goes into making one? Let’s break down the journey from raw materials to finished furniture, and discover where modern solutions like PVC decorative film play a transformative role.

The Cabinet Production Journey: More Than Meets the Eye

While the exact number of steps can vary depending on the cabinet’s complexity, design, materials, and manufacturing scale (bespoke vs. mass production), we can outline the core stages involved. Think of it as typically involving 15-25+ distinct steps, grouped into key phases:

Phase 1: Design & Planning (The Blueprint)

Concept & Specification: Defining the cabinet’s style, dimensions, function, storage needs, and aesthetic preferences (including door/drawer fronts and finishes).

Technical Design & Engineering: Creating detailed technical drawings, cut lists for all parts, and assembly instructions. Calculating material requirements.

Material Selection: Choosing the core materials (particleboard, MDF, plywood, solid wood) and the decorative surface material for visible parts like doors, drawer fronts, and end panels. This is a crucial decision point!

Phase 2: Material Preparation (Cutting & Shaping)

Raw Material Receiving & Inspection: Checking the quality of delivered panels (core boards).

Panel Cutting (Sawing): Using panel saws (manual or CNC) to cut large sheets of core material (like MDF or particleboard) down to the exact sizes specified in the cut list for cabinet boxes, shelves, and internal parts.

Edge Banding (for Box Parts): Applying thin strips of material (usually PVC, ABS, or wood veneer) to the exposed, cut edges of panels used for the cabinet box/shelves to seal them, improve appearance, and increase durability. This often involves specialized edge banding machines (trimming, gluing, pressing).

Door/Drawer Front Cutting & Profiling: Cutting the door/drawer front panels to size. For shaped doors (e.g., shaker style with a recessed panel), additional steps like milling the frame profiles and cutting the panel insert are needed using CNC routers or shapers.

Phase 3: Surface Decoration (Where Aesthetics & Protection Meet)

This phase is where the choice of surface material drastically impacts the number and complexity of steps!

Sanding (Multiple Steps): Essential for paint and veneer. Requires coarse to fine sanding for a perfectly smooth base, often done several times (before and after priming/veneer application). Dusty and labor/time-intensive.

Priming: Applying a base coat (primer) for paint to ensure adhesion and a uniform finish. Needs drying/curing time.

Applying the Decorative Surface:

Paint: Multiple spray coats (base color, top coats), sanding between coats, final curing. Highly dependent on skill, prone to drips/runs, requires significant drying space/time, VOCs.

Veneer: Applying thin wood sheets with adhesive (cold or hot press), trimming excess, sanding, staining, and clear coating (lacquer/varnish). Sensitive to moisture, can chip, complex finishing.

Laminate (HPL): Cutting laminate sheets to size, applying contact adhesive to both surfaces, carefully positioning, and pressing (often with a roller press). Heavy sheets, risk of chipping edges, visible seams on edges.

Final Finishing (for Paint/Veneer): Additional protective clear coats, polishing.

The PVC Decorative Film Advantage:

Film Preparation: Unrolling the PVC film roll and cutting it to the required size (slightly oversized) for the door/drawer front panels. Minimal waste. (Often integrated into lamination step).

Surface Preparation (Minimal): Light sanding or cleaning of the substrate (MDF, plywood) to ensure it’s smooth, clean, and dry. Significantly less work than traditional methods!

Lamination (The Key Step): Applying the PVC film using either:

Vacuum Membrane Press: The most common and efficient method. The film and substrate are placed in a press. A flexible membrane lowers, and vacuum suction pulls it down tightly, bonding the film to the substrate using heat-activated adhesive (pre-applied to the film’s back) or a liquid adhesive. Heat and pressure ensure perfect adhesion and contouring, even over profiled edges. Fast, consistent, and high-quality.

Cold Roller Lamination: Suitable for flat panels. Adhesive is applied to the substrate or film, and rollers press the film onto the substrate. Requires careful alignment.

Trimming: Using precision knives or CNC routers to trim away the excess film cleanly along the edges immediately after pressing (while still warm) or later. Produces a seamless, finished edge.

(Optional) Edge Banding: If the door has a visible frame edge (e.g., shaker style), PVC edge banding is applied after the film is laminated to the front panel, matching perfectly. Automated edge banding is highly efficient.

Key Takeaway: Using PVC film eliminates multiple sanding, priming, painting, and complex finishing steps. The core surface decoration process is streamlined to preparation, lamination, and trimming – often completed in minutes per panel under a press.

Phase 4: Assembly & Hardware

Drilling Hinge & Hardware Holes: Precisely drilling holes for hinges, drawer slides, handles/knobs, and shelf pins using templates or CNC machines.

Cabinet Box Assembly: Joining the cut, edged, and sometimes pre-finished (for interiors) box panels (sides, top, bottom, back, shelves) using fasteners (screws, dowels, cam locks) and glue. Squaring the box is critical.

Installing Drawer Boxes: Assembling drawer sides, front, back, and bottom, and attaching drawer slides to the cabinet box and drawer.

Attaching Doors & Drawer Fronts: Mounting the finished doors and drawer fronts to the cabinet box using hinges and attaching drawer fronts to the drawer boxes.

Installing Handles/Knobs: Adding the final hardware touches.

Phase 5: Quality Control, Packaging & Shipping

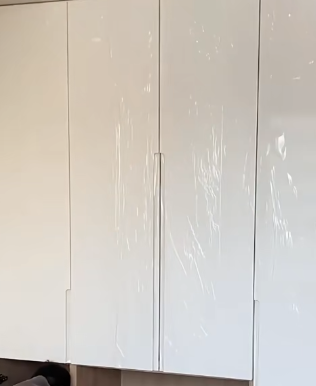

Final Inspection: Checking dimensions, squareness, surface finish quality (no bubbles, scratches, perfect edges), hardware function, and overall appearance.

Cleaning: Removing any dust or residues.

Protective Packaging: Wrapping components to prevent damage during transit.

Packaging: Placing components securely in boxes.

Shipping: Sending the finished cabinets to distributors, retailers, or directly to the customer/installation site.

Why PVC Film is a Game-Changer in Cabinet Production

As we’ve seen, the choice of surface material significantly impacts the Surface Decoration phase. PVC decorative film offers compelling advantages that streamline manufacturing and deliver superior results:

Radically Reduced Steps & Time: Eliminates numerous laborious, time-consuming steps like sanding, priming, multi-coat painting (with drying times), and complex finishing. Lamination is fast and efficient.

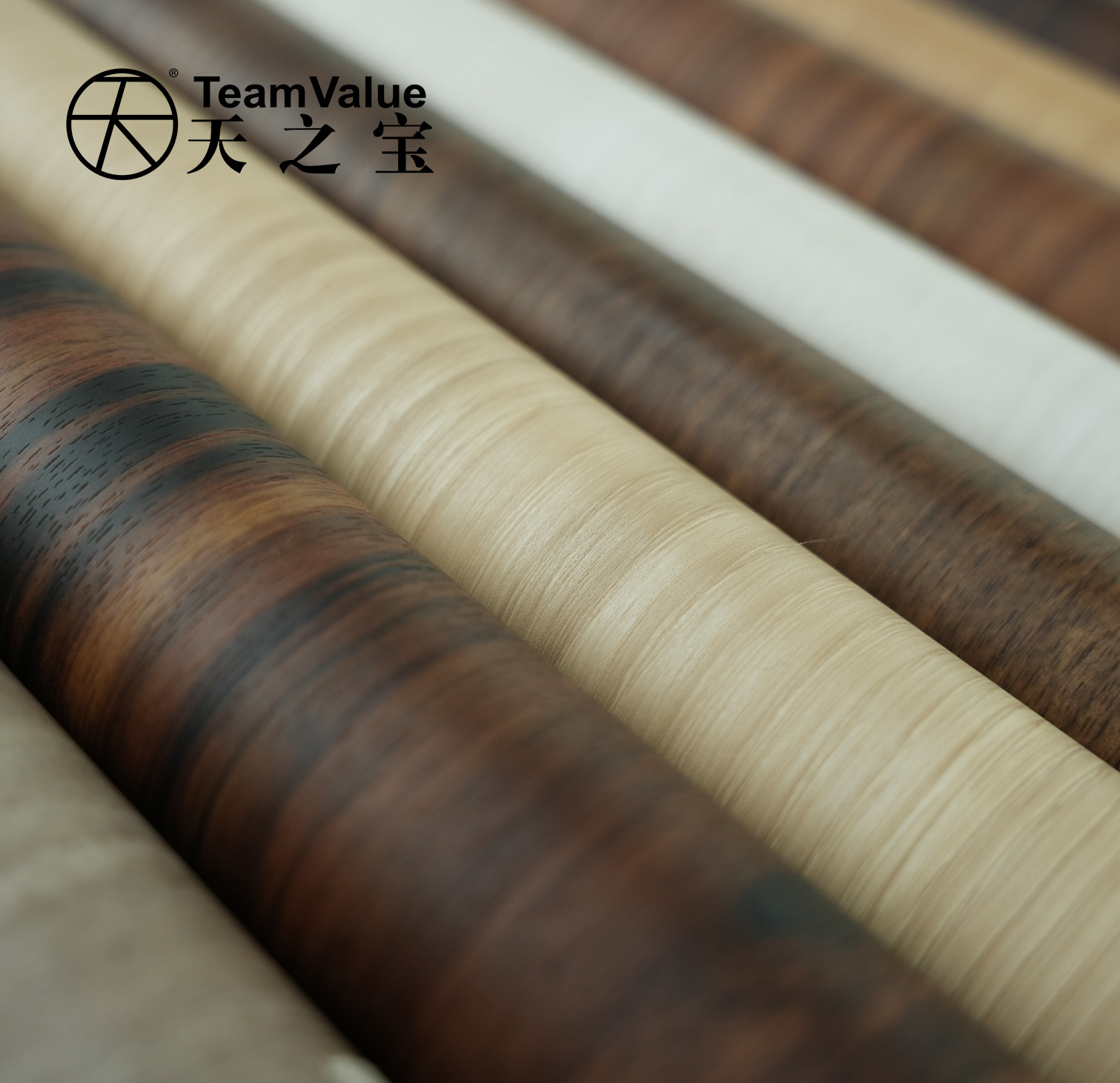

Consistent, High-Quality Finish: Delivers a flawless, uniform surface every time. No brush/roller marks, drips, uneven staining, or sanding imperfections. Advanced textures and prints offer incredible realism.

Enhanced Durability & Performance: Highly resistant to scratches, impacts, moisture, stains, heat (compared to paint), and fading. Easy to clean and maintain – ideal for the demands of kitchens and bathrooms.

Cost-Effectiveness: Reduces labor costs, material waste (paint overspray, sanding dust), energy consumption (drying ovens), and factory space needed for drying/storage. Faster production = higher output.

Design Versatility & Customization: Available in an endless array of colors, wood grains, stones, metals, patterns, and textures. Digital printing allows for unique custom designs.

Improved Working Environment: Minimizes sanding dust and VOC emissions associated with painting/staining, creating a cleaner, safer factory floor.

Conclusion: Efficiency Meets Beauty

Producing a high-quality cabinet is a complex dance of design, material science, and precise manufacturing. While the journey involves many steps (typically 15-25+), innovations like PVC decorative film dramatically simplify and enhance the most critical phase: surface finishing.

By choosing PVC film for cabinet doors and fronts, manufacturers achieve:

l Faster production cycles

l Lower production costs

l Unmatched finish consistency and durability

l Greater design flexibility

l A more sustainable process

At Team Value, we specialize in providing high-performance PVC decorative films specifically engineered for the demands of cabinet manufacturing. Our films offer the perfect blend of stunning aesthetics, exceptional durability, and processing efficiency to help you build better cabinets, faster.