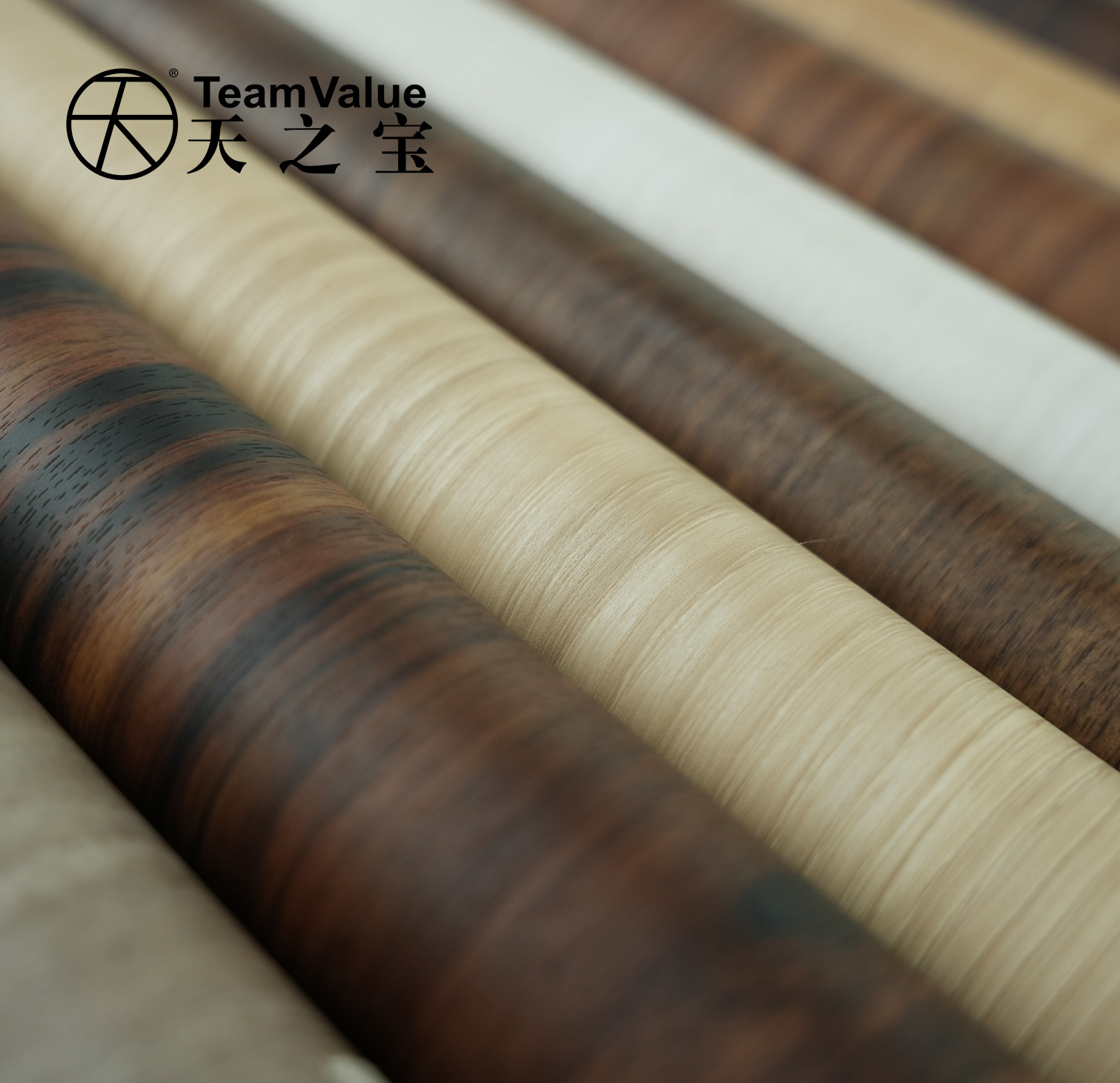

PVC decorative films (woodgrain, stonegrain, and fabric patterns) have become essential materials for modern interior design. Used on walls, furniture, doors, and countertops, these films combine aesthetics with functionality. However, quality varies significantly between products. Next,let Team Value tell you how to choose high-quanlity PVC decorative film.

1. Visual Inspection

Start by examining the film's surface under proper lighting (D65 standard recommended). High-quality PVC film should display:

Consistent pattern repetition without misalignment

No visible defects like scratches, bubbles, or contamination

Uniform color without blotches or fading

Team Value special reminder,For woodgrain films, check that grain lines appear natural and continuous.

2. Physical Performance Tests

Durability is crucial for decorative films. Key tests include:

Scratch resistance: Perform a blade resistance test by making controlled knife cuts (45° angle, 500g force) on the surface. Premium PVC decorative films demonstrate complete blade mark resistance under these conditions.

Stain resistance: Apply common stains (soy sauce,coffee, ink) for 24 hours, then wipe clean. Quality films leave no permanent marks.

Peel strength: Perform a pull test by forcefully stretching the PVC decorative film - premium quality products will show no delamination or surface damage.

3. Environmental Stability

Good PVC film should withstand:

Temperature changes: Test by cycling between -20°C and 60°C (20 cycles). The film shouldn't crack or warp.

UV exposure: After 300 hours in a QUV tester, color change (ΔE) should be ≤2.5.

Humidity: 95% RH exposure for 48 hours shouldn't cause edge lifting.

4. Safety Compliance

Ensure the film meets:

Formaldehyde emission standards (≤0.5mg/L for premium products)

Phthalate content limits (≤0.1% DEHP/DBP/BBP)

Fire ratings (at least Class C per EN 13501-1)

5. Application Performance

Evaluate:

Conformability: The film should smoothly wrap around 90° edges without cracking

Air release: Bubbles should disappear within 24 hours of application

Repositioning time: At least 5 minutes for proper alignment

Quick Quality Checklist:

✓ Pattern clarity and color consistency

✓ No surface defects under 20x magnification

✓ Passes basic scratch/stain tests

✓ Meets safety standards for your region

✓ Performs well in your specific application tests

For critical projects, consider professional lab testing. Reputable manufacturers provide test reports for key parameters. Remember, investing in quality PVC film reduces maintenance costs and extends the lifespan of your interior surfaces.