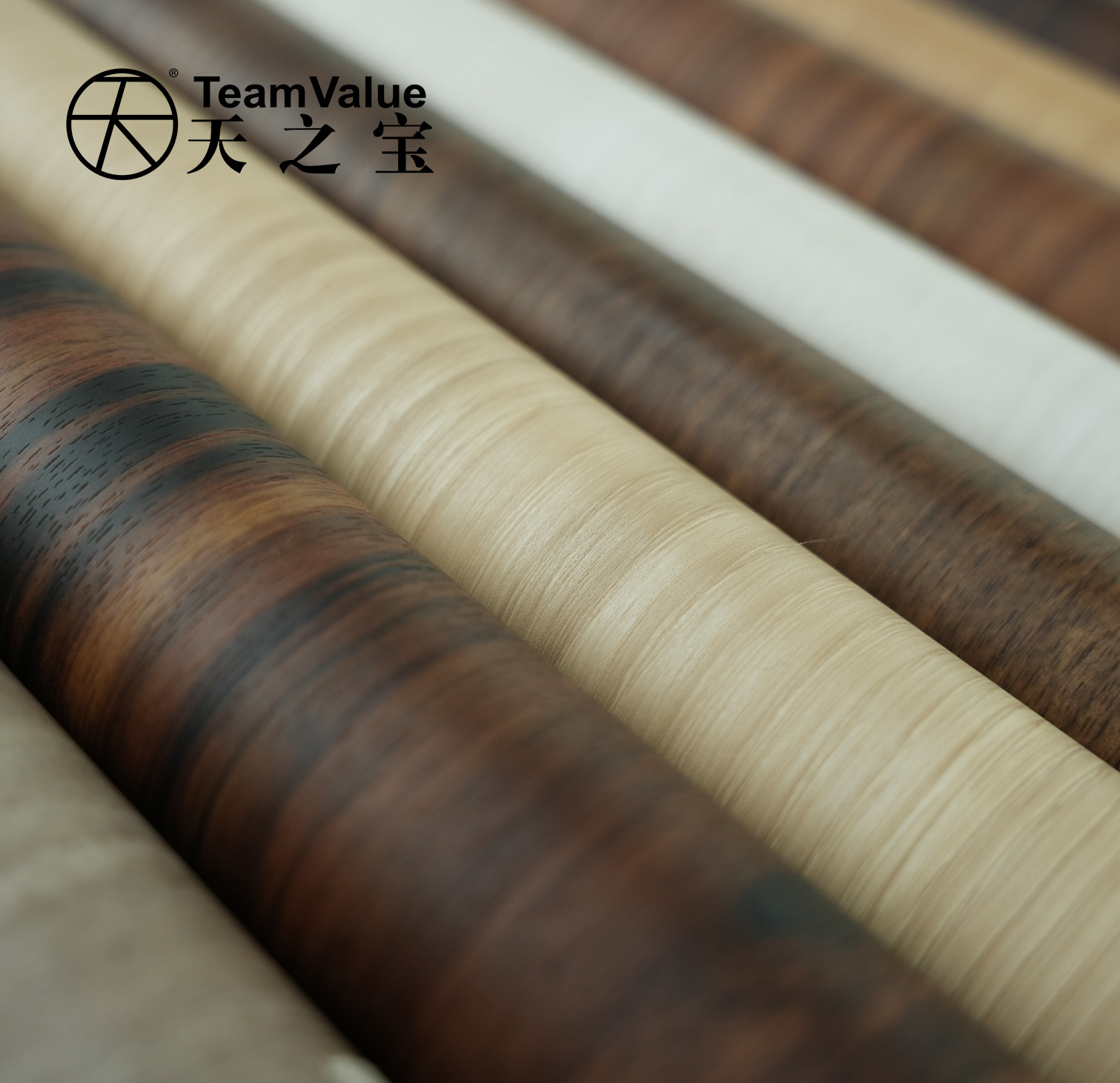

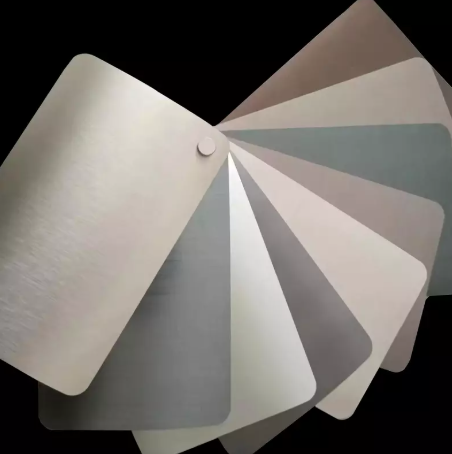

Understanding PET Metallic Film

One of the main advantages of PET metal film is its cost - effectiveness. Compared to using real stainless steel sheets, PET metal film is much more affordable, making it an ideal choice for projects with budget constraints. Additionally, it is lightweight and easy to handle, reducing installation time and effort.

Preparing the Surface

Measuring and Cutting the Film

Once you have the measurements, carefully cut the PET metal film using a sharp pair of scissors or a utility knife. Be precise in your cuts to avoid any uneven edges. If you are working on a large area, you may need to cut multiple pieces of the film and join them together. In such cases, make sure to overlap the edges slightly for a smooth transition.

Applying the PET Metalllic Film

Peel and Stick Method

Start by peeling off a small section of the backing paper from one corner of the PET metal film. Be careful not to touch the adhesive side of the film with your fingers, as this can leave fingerprints and affect the adhesion.

Slowly place the exposed adhesive side of the film onto the prepared surface, starting from the corner where you peeled the backing paper. Smooth out the film as you go, using a squeegee or a flat, hard object. This helps to remove any air bubbles that may form between the film and the surface.

Continue peeling the backing paper and applying the film in sections, making sure to keep the film straight and aligned. If you notice any wrinkles or air bubbles, stop immediately and use a pin to prick the bubbles and then smooth them out with the squeegee.

Using a Spray Adhesive (Optional)

For larger projects or surfaces that may be more difficult to adhere to, you can use a spray adhesive. Apply a thin, even layer of spray adhesive to the prepared surface. Make sure to follow the manufacturer's instructions for the proper application distance and drying time.

After the adhesive is tacky, carefully place the PET metal film onto the surface and smooth it out using a squeegee, following the same process as the peel - and - stick method.

Finishing Touches

Once the PET metal film is fully applied, you may need to trim the edges for a clean, professional look. Use a sharp utility knife or scissors to carefully cut along the edges of the surface, removing any excess film. You can also use a heat gun on a low setting to gently heat the film. This helps to further bond the film to the surface and enhance its durability. However, be careful not to overheat the film, as it can cause it to warp or melt.