PVC Decorative Film's Poor Weather Resistance Leads to Short Outdoor Lifespan - How to Solve It?

普通PVC膜(左)vs 耐候型PVC膜(右)

When exposed to sunlight and rain, standard PVC decorative films suffer from three fatal attacks:

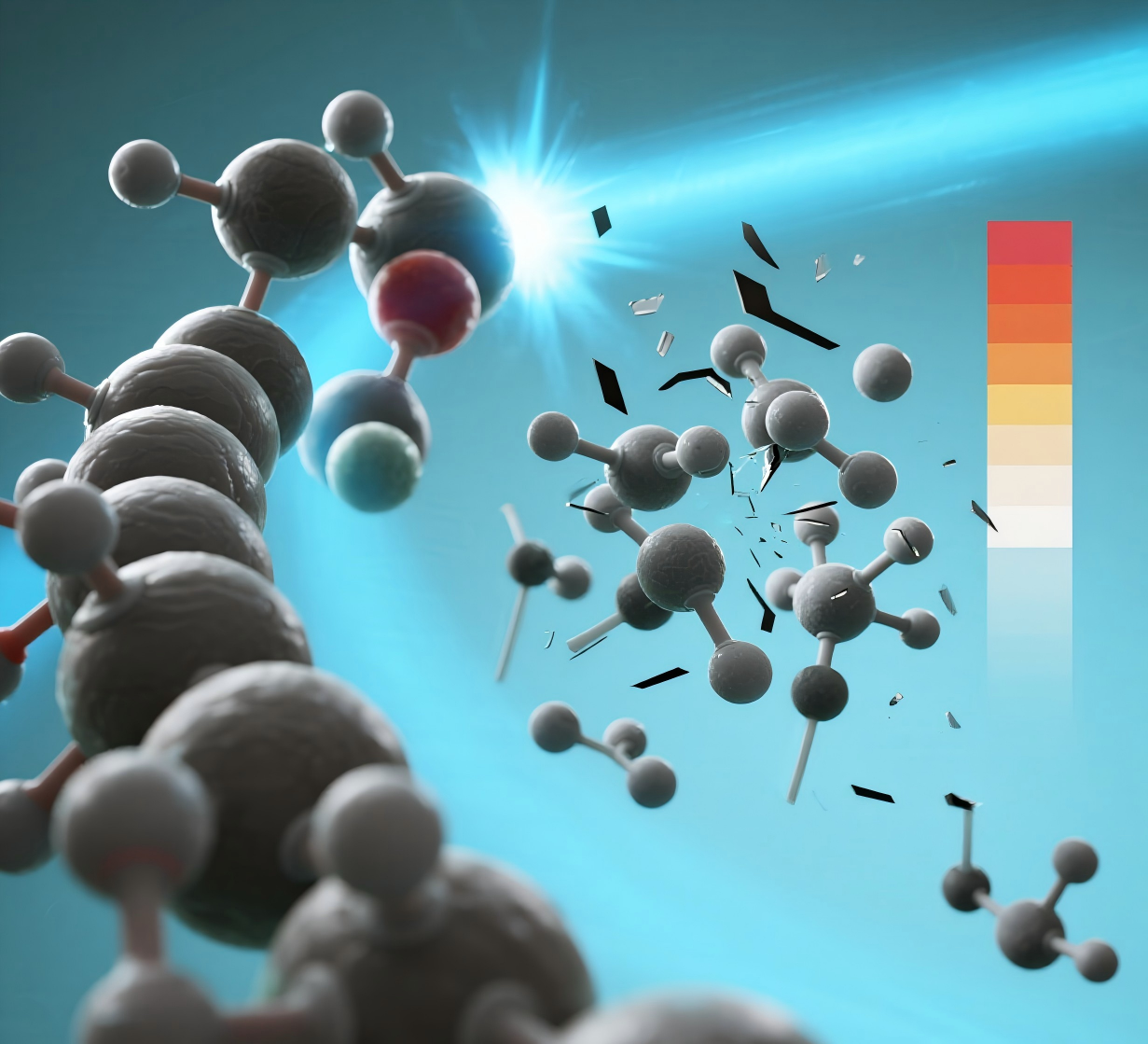

UV Radiation - The Color Killer

Ultraviolet rays break down polymer chains, causing:

Fading and yellowing (ΔE>5 after 500hr QUV test)

Surface embrittlement (Elongation reduced by 60%)

Thermal Cycling - The Stress Amplifier

Daily temperature swings (-20℃~70℃) create expansion/contraction stress:

Edge lifting and bubbling

Microcracks that allow moisture penetration

Hydrolysis - The Hidden Corrosion

Water molecules hydrolyze plasticizers:

Loss of flexibility (Hardness increase >15 Shore A)

Chalking and surface erosion

5 Scientific Solutions to Extend Lifespan to 8+ Years

Solution 1: UV Absorber + HALS Synergy

Mechanism:

UV absorbers convert UV to heat, while Hindered Amine Light Stabilizers (HALS) neutralize free radicals

Data:

Extends color retention (ΔE<3 after 2000hr QUV)

Solution 2: Nano-Ceramic Reinforced Coating

Structure:

20μm acrylic base layer

5μm SiO₂/Al₂O₃ ceramic particles (fills microscopic pores)

Fluoropolymer top coat

Benefits:

Water contact angle >110° (super hydrophobic)

Solution 3: Plasticizer Migration Blocking Technology

Innovation:

Cross-linked polymer networks trap plasticizers

Result:

Plasticizer loss <5% after 3 years outdoor (vs 25% in standard film)

Solution 4: Thermal Stress Relief Design

Technology:

Elastic intermediate layer (EVA copolymer) absorbs expansion

Performance:

Passes 100 cycles of -30℃↔80℃ thermal shock test

Solution 5: Heavy Metal-Free Stabilizers

Environmental Upgrade:

Replaces toxic lead/Cd stabilizers with Ca-Zn complexes

Certification:

Complies with REACH, RoHS, and EU EN 13501-1 fire standard

Selection Guide: 4 Critical Parameters for Outdoor Use

When purchasing weather-resistant PVC film, demand test reports for:

QUV Accelerated Aging: >4000hrs with ΔE<3, gloss retention >80%

Thermal Cycling: Pass -40℃~85℃ for 50 cycles

Water Resistance: Immersion 7 days without blistering (ISO 2812-2)

Plasticizer Content: >30% for low-temperature flexibility

Industry Alert: Beware of "all-weather" claims without certification data!

The Future: Smart Self-Healing Films

Emerging technologies will revolutionize weather resistance:

Microcapsule Technology: Releases healing agents when cracked

Thermally Responsive Polymers: Automatic sealing at 50℃+

Our R&D Progress: Lab prototype achieves 92% scratch recovery