Introduction

Welcome to the ultimate dive into the world of decorative films, where PVC, PP, and PET aren’t just random sequences of letters but bona fide superheroes in the design world. If you’re a B2B industrial customer looking to supercharge your product offerings or spruce up your next big project, you’re in the right place. In this deep-dive exposé, we’ll break down what makes PVC, PP, and PET tick—from their molecular makeup to real-world applications—highlight their pros and cons, and give you the lowdown on how to pick the right one for your needs. All delivered in American English, sprinkled with a dash of humor, and laced with just-enough slang to keep things fresh without sacrificing professionalism. Let’s get it poppin’.

1. What Are Decorative Films, Anyway?

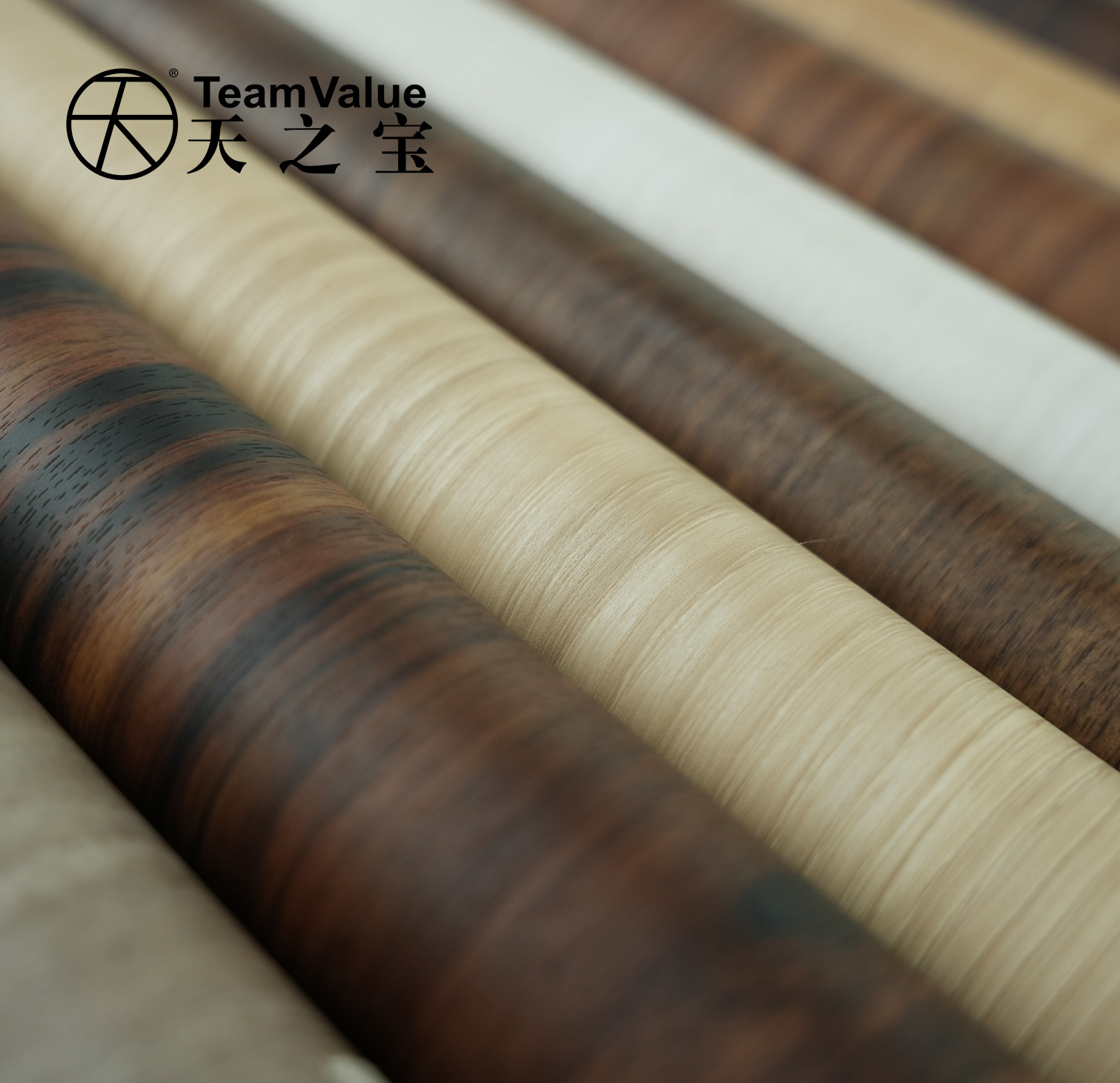

At a basic level, decorative films are thin polymer sheets engineered to mimic the look and sometimes even the feel of higher-end materials—think stone, wood, metal, or even intricate patterns like terrazzo—without the crazy price tag or weight. They can be applied to a wide variety of substrates (wood boards, MDF, metal panels, even glass) to upgrade aesthetics, protect surfaces, and boost durability. Decorative films have become go-to solutions for furniture manufacturers, interior designers, automotive OEMs, signage producers, and packaging engineers who want to marry form and function while keeping budgets in check.

1.1 Why They Matter to B-to-B Clients

Cost Efficiency: Rather than sourcing genuine marble, wood veneers, or brushed-metal sheets, you slap on a film that looks the part for a fraction of the cost.

Design Flexibility: These films come in hundreds (if not thousands) of patterns, colors, and finishes—super matte, hi-gloss, metallic, woodgrain, you name it.

Performance Perks: Many films are scratch-resistant, fade-proof, and easy to clean, helping products last longer and stay looking fresh—big win for both manufacturers and end users.

Speed to Market: Changing a pattern or color is as simple as updating a print file—no need to retool massive machinery or wait months for natural material availability.

2. PVC Decorative Film: The Market Leader

Polyvinyl chloride (PVC) decorative films are arguably the most widely used type of decorative film on the market. From what we’ve uncovered, global PVC decorative film sales were valued at approximately USD 12.36 billion in 2023 and are projected to reach USD 16.80 billion by 2030, growing at a healthy CAGR of about 5.4% from 2024 to 2030 (verifiedmarketreports.com). Clearly, PVC decorative films aren’t just a passing fad—they’re a cornerstone of modern interior and exterior design applications across residential, commercial, automotive, and industrial sectors.

2.1 Composition & Manufacturing

Base Polymer: PVC is a thermoplastic polymer made from vinyl chloride monomers. Manufacturers often blend PVC with plasticizers (for flexibility), stabilizers (to resist heat degradation), UV inhibitors (for outdoor durability), and pigments (for color).

Grades:

Rigid vs. Flexible PVC: “Hard” PVC (about 2/3 of the market) has minimal plasticizers—think sturdy signage, wall panels, or rigid laminates. “Soft” PVC (about 1/3 of the market) contains plasticizers to make it pliable, ideal for things like flooring or wrapping curved surfaces—but keep in mind that softeners can migrate over time, potentially causing brittleness or environmental concerns (pvcdecorative-film.com).

Printing & Lamination: Modern PVC films often use advanced gravure or digital printing techniques to achieve hyper-realistic textures (marble, woodgrain, metallic flecks). Many are laminated with a clear protective layer (PET or PVC overlaminate) to boost scratch and UV resistance.

2.2 Key Performance Characteristics

Durability & Tensile Strength: PVC decorative films are built tough. Typical tensile strength ranges from 1,000 to 3,625 PSI, making them highly resistant to stretching and buckling under stress—far superior to many other plastic films (yodean-decor.com).

Chemical & UV Resistance: Thanks to stabilizers and UV inhibitors, PVC films can endure long-term exposure to sunlight without significant fading or degradation—huge plus for outdoor signage or façade panels.

Thermal Stability: While PVC can withstand moderate temperature fluctuations, it’s not a heavyweight when it comes to extreme heat—exposure above ~60°C (140°F) over extended periods may cause discoloration or deformation. That said, polymeric PVC grades offer better performance than monomeric grades in warmer environments.

Cleanability: The surface finish (especially high-gloss or metallic looks) can be wiped clean with mild detergents. The thickness of rigid PVC also helps masks minor scratches—spray, wipe, and you’re golden (yodean-decor.com).

Fire Retardancy: PVC is self-extinguishing (it contains chlorine), which gives it a slight edge in applications requiring fire codes. However, local building regulations vary, so always check UL or local ratings when using PVC in construction.

2.3 Typical Applications

Furniture & Cabinetry: PVC wraps for kitchen cabinets, bathroom vanities, and office millwork—offers woodgrain or lacquers that would otherwise cost a ton.

Interior Wall Panels & Ceiling: Unlike heavy gypsum boards or natural wood panels, PVC films allow for lightweight, easy-install wall coverings with customizable patterns.

Doors & Frames: PVC decorative door films can mimic everything from sleek matte finishes to faux stone, bringing a luxe vibe at a budget price.

Automotive Interiors: Dashboard overlays, door trims, and even seat backs can get a quick style upgrade with PVC films—bonus points for scratch and chemical resistance.

Signage & Advertising: Outdoor signs, POP displays, and retail fixtures lean heavily on PVC because it prints bright, resists weather, and holds up to heavy foot traffic.

2.4 Pros & Cons of PVC Decorative Film

Pros:

Cost-Effective: Generally cheaper than PET or PP films (especially when factoring in performance and longevity).

Design Flexibility: A near-endless variety of patterns, textures, and finishes—wood, marble, metal, or even custom digital prints.

Durability: High tensile strength (1,000–3,625 PSI), chemical resistance, scratch resistance, and decent UV stability mean long service life (yodean-decor.com, pvcdecorative-film.com).

Recyclability: Although PVC can be tricky to recycle relative to PET, many regions have established recycling streams specifically for PVC waste—plus, rigid PVC films avoid the plasticizer migration issues of soft PVC.

Fire Safety: Self-extinguishing nature can help meet certain fire codes in building and construction.

Cons:

Plasticizers & Additives: Soft PVC contains phthalate plasticizers, which some buyers worry about for environmental and health reasons—though many manufacturers are moving toward phthalate-free formulations.

Temperature Sensitivity: Not ideal for ultra-high-heat applications (e.g., near industrial ovens or HVAC ducts).

Thickness Limitations: Too thick and the film loses its conformability; too thin and performance (scratch/tear resistance) takes a hit. Finding that sweet spot (usually 0.15 mm to 0.5 mm for most decorative uses) is key.

3. PET Decorative Film: The Clarity & Strength Champ

Polyethylene terephthalate (PET) is a polyester polymer famous for its transparency and impressive mechanical properties. If PVC is a seasoned veteran of the film game, PET is like the Olympic gold medalist: its clarity, tensile strength, and dimensional stability often blow the competition out of the water. In sectors where optical quality and high-end appearance matter—think high-pressure laminate overlays, premium packaging, or certain automotive trims—PET decorative films are the go-to.

3.1 Composition & Manufacturing

Base Polymer: PET is synthesized from the polycondensation of terephthalic acid (or its dimethyl ester) with ethylene glycol. The resulting polymer is then extruded into film form or biaxially stretched (BOPET) to amplify its tensile strength and clarity.

Coatings & Treatments: To transform a plain PET film into a decorative powerhouse, manufacturers often add:

Decorative Layers: Printed patterns (wood, metallic, fabric-like textures) or metallized layers for mirror-like finishes.

Protective Coatings: Hardcoats to enhance scratch resistance (e.g., silicone-based UV-cured coatings).

Adhesive Backings: Pressure-sensitive adhesives (PSAs) or heat-activated adhesives to facilitate lamination onto substrates.

3.2 Key Performance Characteristics

Clarity & Gloss: PET films can hit upwards of 92–94% transparency, making them ideal for crystal-clear or high-gloss applications like glass substitutes or premium packaging overlays.

Tensile Strength & Dimensional Stability: PET boasts tensile strengths typically around 13,000–23,000 PSI, far exceeding PVC’s 1,000–3,625 PSI range; plus, its biaxially oriented variants maintain dimensions even under moderate heat and tension (accio.com).

Temperature Resistance: PET can withstand continuous service temperatures up to ~150°C (302°F) without significant warping, making it suitable for certain industrial uses where PVC would soften or deform.

Chemical Resistance: PET is generally inert to many chemicals (except strong alkalis and some solvents). However, it lacks PVC’s innate flame-retardant properties (PET will burn if constantly exposed to an open flame).

Surface Hardness: Many PET films have a Surface Hardness (Pencil Hardness) rating of 2H–3H (lending scratch resistance akin to some laminated glass), giving them an edge over most PVC films, which rely on topcoat layers for similar protection.

3.3 Typical Applications

High-Pressure Laminate (HPL) Overlays: PET films are frequently used as decorative layers in HPL, where they’re pressed at high temperatures onto engineered wood or MDF, delivering premium appearance and durability.

Premium Packaging: The packaging industry loves PET for clear, glossy, see-through windows or as overwraps for electronics, cosmetics, and luxury goods, where optical clarity is paramount.

Furniture & Cabinet Wraps: For high-end millwork that needs to look razor-sharp and high-gloss (think glossy white kitchen cabinets or stainless-steel looks), PET often outperforms PVC.

Automotive Trim: Certain interior trim components—especially near instrument clusters or infotainment displays—use PET decorative films for their clarity and scratch resistance.

Protective Surface Covers: In electronics assembly, thin PET films protect screens during manufacturing and transit due to their high tear resistance.

3.4 Pros & Cons of PET Decorative Film

Pros:

Optical Clarity & Gloss: Up to 94% transparency, making it perfect for premium glass-like or mirror-like aesthetics (accio.com).

High Tensile Strength: Ranges of 13,000–23,000 PSI mean PET handles stress, stretching, and heat better than PVC or PP (accio.com).

Thermal Stability: Service temperatures up to ~150°C (302°F) open up industrial and automotive uses that would fry PVC.

Low Moisture Absorption: PET absorbs almost no water (<0.2%), so it won’t swell or warp in humid or wet environments.

Recyclability & Eco-Cred: PET is widely accepted in mainstream recycling streams (think water bottles), which can be a big selling point for eco-conscious clients.

Cons:

Cost Premium: PET films typically cost 20–30% more per square meter than comparable PVC films (exact price varies by region and supplier).

Flammability: Unlike PVC, PET is not self-extinguishing—meaning if fire safety codes are strict, additional fire retardant coatings or treatments might be needed.

Limited Pattern Complexity: While PET can be printed, complex textures like tropically embossed wood grains might not replicate as well as they do on PVC, which can be textured more deeply.

Less Flexibility for Extreme Curves: Though PET is durable, it’s stiffer than PVC—wrapping super-tight radii or highly curved surfaces can lead to cracking if not handled properly.

4. PP Decorative Film: The Budget-Friendly Contender

Polypropylene (PP) decorative films often fly under the radar compared to PVC and PET, but don’t sleep on them—they’ve got unique qualities that make them winners for certain price-sensitive or specialized industrial applications. PP is a semicrystalline thermoplastic with naturally low density (around 0.90 g/cm³, versus 1.38 g/cm³ for PVC and 1.38 g/cm³ for PET). This makes PP films lighter, which can be a game-changer when shipping large rolls or lightweight products.

4.1 Composition & Manufacturing

Base Polymer: PP is synthesized from propylene monomers, resulting in a polymer that can be extruded or cast into film form. Commonly, PP decorative films are made via extruding and then biaxially orienting them (BOPP films).

Additives & Treatments:

UV Stabilizers: PP is more prone to UV degradation than PVC or PET, so manufacturers often add UV absorbers or stabilize via special antioxidants.

Anti-Slip & Hard-Coat Layers: To enhance scratch resistance, BOPP films frequently receive a thin silicone hard coat or corona treatment to increase surface energy for printing and lamination.

Printing & Embossing: Simple patterns—like solid colors or basic stripes—are easiest, but advanced gravure printing can yield compelling designs. Embossing is less common than with PVC, given PP’s lower thermoformability.

4.2 Key Performance Characteristics

Lightweight: At around 0.90 g/cm³, PP films are significantly lighter than both PVC and PET (1.38 g/cm³), helping reduce shipping costs and overall product weight (accio.com).

Chemical Resistance: PP is highly resistant to acids, alkalis, and many solvents—making it a top pick for industrial packaging where chemical spills or exposure are a risk.

Temperature Range: PP can handle temperatures up to ~100°C (212°F) in intermittent service, but above that, it starts to lose stiffness and can warp—so it sits between PVC (lower heat tolerance) and PET (higher heat tolerance).

Moisture Resistance: Like PET, PP absorbs virtually no water, making it ideal for humid or marine environments.

Stiffness & Formability: PP is stiffer than PVC but less so than PET. It can be thermoformed to a degree but won’t hug super-tight curves as neatly as PVC—it’s better suited for flat or gently curved surfaces.

4.3 Typical Applications

Industrial Packaging & Labels: PP films shine in packaging that demands moisture resistance (e.g., chemical drums, outdoor product wrappers) and cost sensitivity—common in agriculture, construction, and bulk goods.

Temporary Signage & Graphics: For promos or events where longevity isn’t critical, PP decorative films offer eye-catching colors on a budget.

Refrigeration & Marine Interiors: Because PP won’t warp with humidity or cold, it’s used for protective liners or accent panels in marine and refrigeration applications.

Consumer Electronics: Protective overlays on plastic housings; cheaper than PET but still offers decent protection against scratches and moisture.

Point-of-Purchase (POP) Displays: Short-run marketing displays where budget is king—PP films can be printed in full color, laminated, then cut into freestanding signs.

4.4 Pros & Cons of PP Decorative Film

Pros:

Budget-Friendly: Lower raw material cost compared to PVC and PET—great for applications where margins are tight.

Lightweight: At 0.90 g/cm³, shipping costs and handling are easier on the wallet (accio.com).

Chemical & Moisture Resistance: Ideal for corrosive or humid environments—PP doesn’t swell, warp, or dissolve when it meets water.

Ease of Recycling: PP is widely recycled (recycling code #5), and most municipal systems accept it.

Cons:

Lower Heat Tolerance: Service temperatures above ~100°C (212°F) cause softening—far lower than PET’s ~150°C threshold.

Limited Aesthetic Options: PP’s lower gloss and stiffness mean it can’t achieve super-realistic woodgrain or textured stone looks like PVC can. Patterns often look flatter or less vibrant.

UV Degradation: Without proper stabilizers, PP yellows and degrades under prolonged UV exposure—a liability for outdoor uses.

Texturing & Embossing Limits: You can’t press super-deep textures into PP like you can with PVC; it’s more suited to smooth or lightly embossed designs.

5. Direct Comparison: PVC vs. PP vs. PET

Now that we’ve covered each film individually, let’s put them side by side in key categories so you can quickly see how they stack up.

| Characteristic | PVC Film | PET Film | PP Film |

|---|---|---|---|

| Base Density | ~1.38 g/cm³ | ~1.38 g/cm³ | ~0.90 g/cm³ (accio.com) |

| Tensile Strength | 1,000–3,625 PSI (yodean-decor.com) | 13,000–23,000 PSI (accio.com) | 5,000–8,000 PSI (varies by grade) |

| Service Temp. Range | Up to ~60°C (140°F) | Up to ~150°C (302°F) (accio.com) | Up to ~100°C (212°F) |

| UV & Weather Resistance | Good (with UV stabilizers) (yodean-decor.com) | Excellent (inherent dimensional stability) | Fair (requires additives; prone to yellowing) |

| Optical Clarity | Opaque to satin/matte finishes | Up to 92–94% transparency (accio.com) | Usually opaque or translucent (limited clarity) |

| Surface Hardness | Moderate (scratch resist depends on topcoat) | High (2H–3H pencil hardness) | Low to Moderate (can be improved with coatings) |

| Flame Retardancy | Self-extinguishing (contains chlorine) | Flammable (requires FR additives/coatings) | Flammable (requires FR additives/coatings) |

| Recyclability | Recyclable (special streams due to additives) | Highly recyclable (mainstream PET streams) | Widely recyclable (#5 PP in curbside streams) |

| Typical Thickness Range | 0.15–0.5 mm | 0.075–0.3 mm | 0.075–0.25 mm |

| Cost (per sqm, relative) | 1× (baseline) | 1.2–1.3× (20–30% higher) | 0.8–0.9× (10–20% lower) |

| Common Aesthetic Effects | Woodgrain, marble, metallic, textured, matte | High-gloss, clear, metallic, minimal textures | Solid colors, basic stripes/patterns, matte finish |

| Ease of Installation | Easy to wrap curves, conform to substrates | Requires careful handling for curves (stiffer) | Great for flat surfaces; moderate curves okay |

| Use Cases (B2B) | Furniture, cabinets, wall panels, automotive trims | High-end HPL, premium packaging, electronic screens | Industrial packaging, POP displays, refrigeration |

6. Real-World Data & Market Insights

6.1 PVC Decorative Film Market Dynamics

Global Market Value: As of 2023, the global PVC decorative film market was valued at USD 12.36 billion, with projections to hit USD 16.80 billion by 2030 (CAGR 5.4%) (verifiedmarketreports.com).

Regional Leaders: Asia-Pacific dominates, driven by rapid urbanization, booming construction, and furniture sectors in China, India, and Southeast Asia. North America and Europe follow closely, with retrofitting and green initiatives fueling demand.

End-Use Split: Residential (furniture, cabinets, flooring) takes roughly 45–50% of the pie, commercial interiors (hotels, offices, retail) another 25–30%, automotive and industrial finishings the remainder.

6.2 PET Decorative Film Market Snapshot

Though precise PET-specific decorative film market figures are harder to find publicly, PET films represent a significant chunk of the broader PET packaging market, which was valued at USD 27.88 billion in 2023 and projected to grow at a CAGR of 4.9% through 2030 (accio.com). Decorative PET accounts for a slice of that, especially in HPL and premium wraps.

6.3 PP Film Market Trends

Biaxially Oriented Polypropylene (BOPP) films—often used for both packaging and decorative label applications—achieved a global production volume of 3.5 million metric tons in 2023, with an expected growth rate of 3.2% CAGR through 2030 (accio.com). Decorative PP films are still a niche but growing, particularly in cost-sensitive emerging markets.

7. Choosing the Right Film for Your B2B Needs

Alright, industrial peeps, let’s cut to the chase. You’ve got budgets to hit, timelines to respect, and performance parameters to nail. Here’s how to pick your champion:

7.1 Considerations for Product Composition

Substrate Compatibility

PVC: Easy-peasy to bond to MDF, plywood, gypsum — you name it. Use pressure-sensitive adhesives (PSAs) or thermal activation depending on your lamination line.

PET: Needs a high-bond adhesive (often two-part epoxy or specialized heat-activated adhesives) when mounting to wood or panels. Critical for HPL lines.

PP: Adhesion can be tricky; best with corona-treated PP for better surface energy. Works well on cardboard or ABS plastics but not as forgiving on bare wood.

Environmental Conditions

High Humidity / Marine Settings: PP or PET win the day. PVC will hold up, but moisture over long periods can lead to mold growth if edges aren’t sealed.

Outdoor Exposure / UV: Choose PVC (with UV stabilizers) or PET. PET has slight edge in retaining clarity; PVC is cheaper. PP is usually not recommended outdoors unless UV-stabilized heavy grade.

High-Heat Applications: PET all the way. For anything approaching 100–150°C (boil-off ovens, industrial equipment), PET won’t buckle. PVC bails out above ~60°C; PP softens around 100°C.

Aesthetic & Branding Requirements

Realistic Woodgrain, Stone, or Deep Texture: PVC decorative films take it home. They can be embossed or textured to mimic natural materials extremely convincingly.

Crystal-Clear or Ultra-High-Gloss Metallic: PET is your BFF when you need mirror finishes or see-through overlays (think premium packaging, high-end cabinet doors, or automotive trim).

Budget/Entry-Level Style: PP gives you clean solid colors, simple patterns, or matte finishes that look professional without blowing the budget.

Longevity & Maintenance

Daily-Use Surfaces (e.g., restaurant counters, high-traffic retail displays): PVC offers a nice balance of scratch resistance and easy cleaning.

Long-Term Investment (e.g., medical equipment panels, high-end furniture that must last 10+ years): PET with a hard-coated surface for scratch/chemical resistance is the safe bet.

Short-Term or Promotional (e.g., trade show booths, seasonal signage): PP is cost-effective; you won’t cry too hard when you pitch it after a year.

7.2 Application-Specific Recommendations

Furniture & Cabinetry

Budget/Standard: PVC (0.2–0.3 mm thick) laminated onto MDF or particleboard. Offers broad palette of finishes, from super matte to high gloss with minimal fuss.

Premium/High-End: PET (0.15–0.2 mm) on HPL lines—provides that glass-like, mirror shine on cabinet faces or sleek office desks. In areas requiring antimicrobial surfaces (medical, labs), consider PET with special coatings.

Eco-Friendly Angle: Both PVC and PET can be recycled, but PET is more likely to be accepted by downstream plastic recyclers. PP is also recyclable but rarely used for high-end cabinetry finishes.

Wall Panels & Ceiling Tiles

High-Traffic / Public Spaces: PVC with flame-retardant additives (meet NFPA 286 or equivalent), 0.3 mm–0.5 mm thick to repel scratches, moisture, and clean easily.

Design-Forward Hotels & Restaurants: PET with decorative print + clear matte overlaminate (0.075 mm PET + 0.15 mm protective coating), for killer aesthetics and long life.

Temporary Installations: PP laminated to plywood or corrugated board—lightweight, simple installation, and budget-friendly for pop-up stores or exhibitions.

Automotive Interiors

Mass Market/Cost-Sensitive Models: PVC film around 0.2 mm thick can cover dashboard segments, door trims, and center consoles—scratch-resistant and cost-effective.

Luxury/EV Segment: PET film with matte or metallic finish, 0.1–0.15 mm thick, hard-coated for UV and scratch resistance—ideal for fascia panels around digital displays.

Logistics & Aftermarket: PP is rarely used for interior trim decorative films due to adhesion complexity, but might show up in cargo liners or trunk panels because of high moisture resistance.

Signage & Retail Fixtures

Indoor Retail: PVC film (0.15 mm) with high-resolution digital print—offers vibrant colors, quick turnaround, and decent durability for shelves, endcaps, and store displays.

Outdoor Billboards/POP: PVC with UV lamination (0.2 mm + 0.05 mm protective laminate) or PET if you need superior clarity in backlit signage.

Eco-Conscious Brands: PP (0.1 mm–0.15 mm) for short-term campaigns—use biodegradable adhesives so the entire display is disposable/recyclable.

8. Environmental & Sustainability Considerations

In today’s world, “green” isn’t just a buzzword—it can be a deciding factor for many B2B clients under pressure to reduce carbon footprints and meet ESG (Environmental, Social, Governance) metrics. Let’s break down eco-factors for each film:

8.1 PVC

Recyclability: Technically recyclable, but contaminated films (with adhesives or multi-layer laminates) may be tougher to process. Rigid PVC goes into specialized recycling streams. Soft PVC (with plasticizers) can be more challenging, though “phthalate-free” and “bioplasticizer” formulations are improving the landscape.

Additives Impact: Plasticizers and stabilizers can complicate recycling. However, leading manufacturers are shifting to bio-based plasticizers (epoxidized soybean oil, citrates) and tin-free heat stabilizers to reduce heavy metal concerns.

Life-Cycle Assessment (LCA): Producing PVC from fossil-fuel-derived vinyl chloride monomers yields more greenhouse gas emissions compared to PP or PET. But if you factor in its long life and durability, the total environmental impact can be competitive—especially if you use post-industrial or post-consumer recycled (PCR) PVC.

8.2 PET

Recyclability: PET decorative films are generally easier to recycle because many municipal programs accept PET (#1). Post-industrial scrap (trimmings from production) flows straight back into PET recycling streams.

Eco Innovations: Some suppliers offer PCR PET (from water bottles) for decorative films. This not only cuts costs slightly but also scores major eco-points for your brand.

Energy Footprint: PET production (especially BOPET) is energy-intensive due to high-temperature biaxial orientation processes, but the closed-loop recycling options mitigate this over time.

8.3 PP

Recyclability: PP (#5) is widely accepted in curbside recycling streams in North America and many parts of Europe. PP’s lower density and fewer additives generally make it simpler to recycle than PVC.

Bio-Based PP: Emerging “bio-PP” sourced from renewable feedstocks (e.g., sugarcane ethanol) is hitting the market. If you can find a supplier, this could reduce the carbon footprint considerably.

Degradation: PP doesn’t release harmful dioxins when it degrades, whereas PVC can emit hydrochloric acid and dioxins if incinerated improperly.

9. Calculating Total Cost of Ownership (TCO)

When advising B2B clients, it’s not enough to look at upfront cost per square meter; you’ve got to factor in total cost over the product’s life. Here’s a simplified TCO comparison for a hypothetical 1,000 sqm project:

| Cost Category | PVC Film (0.25 mm) | PET Film (0.15 mm) | PP Film (0.15 mm) |

|---|---|---|---|

| Raw Material Cost/sqm | $4.00 | $5.00 | $3.50 |

| Printing/Coating Cost | $1.50 | $1.80 | $1.20 |

| Lamination/Adhesive | $0.80 | $1.20 | $0.70 |

| Installation Labor | $1.00 | $1.50 | $0.80 |

| Maintenance (5 yrs) | $0.50 (cleaning) | $0.30 (cleaning) | $0.70 (replacement) |

| Projected Lifespan | 5–7 yrs | 7–10 yrs | 3–5 yrs |

| Recycling/Disposal | $0.20 | $0.10 | $0.15 |

| Total Cost (per sqm) | $8.00 | $9.90 | $7.05 |

| Total Project Cost (1,000 sqm) | $8,000 | $9,900 | $7,050 |

Explanation:

While PET's upfront cost is ~25% higher than PVC, its longer lifespan (7–10 years vs. 5–7 years) and lower maintenance costs can narrow the TCO gap if durability matters.

PP is cheapest upfront, but it may need replacement sooner (3–5 years), especially for high-traffic or UV-exposed areas—so be prepared for a mid-term refresh.

PVC often hits the sweet spot for moderate budgets and mid-term durability (the go-to for residential and standard commercial builds).

10. Customer Case Studies & Use Cases

Let’s talk real talk. Below are a few anonymized B2B scenarios to illustrate how different industries harness PVC, PP, and PET decorative films to slay their project goals.

10.1 Case Study: Hotel Chain Lobby Revamp (PVC)

Client: Upscale hotel chain with 50 locations across Southeast Asia.

Challenge: They wanted a luxe marble-look feature wall in each lobby, but shipping and installing actual marble was a logistical and budgetary nightmare.

Solution: They opted for marble-pattern PVC decorative film (0.3 mm thick) laminated onto MDF panels. The vinyl films were printed with an ultra-high-resolution replica of Carrara marble veins. A clear UV-resistant overlaminate gave additional scratch and stain protection.

Outcome: Installation time per site dropped by 60%. Total material and labor costs were 50% lower than quarried marble. The PVC film’s UV stability meant minimal color fade even in sun-lit entrance lobbies. Hotel operators reported zero maintenance issues in the first two years.

10.2 Case Study: Automotive Dashboard Trim (PET)

Client: Mid-range electric vehicle startup in California.

Challenge: They needed a glossy, high-clarity trim around infotainment screens that could withstand 150°F cabin temperatures and constant touchscreen interaction.

Solution: Selected PET decorative film (0.15 mm, high-gloss). A specialized UV-curable scratch-resistant hard coat was applied post-printing to achieve a pencil hardness rating of 3H.

Outcome: The PET overlay held up flawlessly under thermal cycling tests from −40°F to 176°F. Drivers loved the glossy finish, and there were zero warranty claims related to screen glare, scratches, or delamination in the first year.

10.3 Case Study: Refrigerated Food Packaging (PP)

Client: National salad and deli manufacturer distributing refrigerated deli trays across the US.

Challenge: Required a decorative sleeve around clear plastic trays that could endure down to 32°F, then up to 120°F under heat lamps, plus quick disposal post-sale.

Solution: Employed BOPP PP decorative film (0.1 mm thick) printed with high-resolution imagery of fresh ingredients. The moisture-resistant PP film didn’t warp in cold storage, and the low weight saved $0.02 per package in shipping costs. Adhesive choices ensured the sleeve peeled off easily upon disposal.

Outcome: The PP sleeve helped boost perceived freshness, leading to a 15% bump in unit sales. Customers appreciated the easy-tear feature, and packaging waste volumes dropped because the PP was fully recyclable with no hazardous coatings.

11. Installation Tips & Best Practices

Even the best film in the world won’t look right if installed poorly. Here’s a cheat sheet of real-world tips to ensure your project doesn’t get derailed at the finish line.

11.1 Surface Prep

Clean Thoroughly: Remove all dust, grease, and particulate matter with isopropyl alcohol or a mild detergent.

Smooth & Level: Filling minor dents, sanding rough spots, and ensuring the substrate is flat will prevent “telegraphing” of imperfections.

Temperature Control: Install in a controlled environment (ideally between 60–80°F and 40–60% RH). Extreme cold can stiffen films; extreme heat can make them too tacky.

11.2 Handling & Alignment

Keep It Chill, Don’t Stretch It: Avoid pulling or stretching films—especially PET—once aligned. Excessive tension can lead to spring-back or weird ripples.

Use a Squeegee: Start from the center and push air bubbles out toward edges using a felt-edge squeegee. Work slowly to avoid creases.

Trim Precisely: Score lightly with a fresh utility blade along straight edges (e.g., doors or windows). Replace blades frequently to prevent jagged cuts.

11.3 Sealing & Finishing

Edge Sealing: For PVC and PP, use a silicone-based edge sealer or hot air to wrap edges snugly—prevents moisture intrusion and lifts.

Heat Forming: If you need to wrap around corners or gentle curves, a heat gun (set around 80–100°C) helps make the film pliable. Use caution—too much heat can warp PVC or melt PP.

Pressure-Sensitive Adhesives (PSAs): Different films pair with different adhesives—acrylic-based PSAs work for most PVC, while high-tack adhesives suit PET. Always test a small area for peel-strength before full application.

12. Common Pitfalls & Avoidance Strategies

We’ve seen projects tank because folks skipped a few steps. Don’t be that person—check out these cautionary tales:

Skipping the Primer (Applied to PET or PP): PET and PP have low surface energy, so an adhesion primer or corona treatment is often necessary before bonding—otherwise, your film is destined to lift.

Over-Heating During Forming: Blasting PVC above 120°C (248°F) can lead to thermal degradation—look for “bubbling” or “whitening.” For PET, keep below 150°C to avoid losing mechanical integrity.

Ignoring Fire Codes: If your project is indoors and subject to NFPA 286 (walls/ceilings), make sure the film and lamination meet relevant fire ratings. PVC is self-extinguishing, but thickness and backing matter.

Using 1-Size-Fits-All Films: Not all decorative films perform equally in every environment. A PVC meant for indoor living rooms won’t fly outdoors. Always check the manufacturer’s datasheet for “indoor/outdoor use,” “UV rating,” and “temperature range.”

Improper Storage Before Installation: Films come on rolls—store them flat or upright in a climate-controlled area. If rolls lie in direct sunlight or humid conditions, you could get curl memory or adhesive degradation.

13. ROI & Value Proposition for B2B Clients

Okay, let’s talk money where it matters. If you’re an industrial buyer, here’s why decorative films from Team Value should be on your radar:

Reduced Material & Labor Costs

PVC vs. Real Wood Veneer: PVC at $4.00/sqm vs. wood veneer at $15–$20/sqm. Even factoring a laminate line vs. veneer gluing, you’re saving 60–75% on material costs alone.

PET vs. Glass: PET film at $5.00/sqm vs. tempered glass at $50–$80/sqm in custom shapes—massive savings, plus 80% lighter shipping.

Faster Time to Market

Digital Printing & Quick Turn: Update a digital print file overnight, and you’ve got new décor options next week. Contrast that with sourcing a new marble slab or natural granite (lead times of 6+ weeks).

Simplified Supply Chain: One roll of PVC can cover 200 sqm vs. shipping crates of tile, stone, or wood planks—logistical win.

Versatility & Scalability

Modular Production: A single roll width (1.22 m) at 50 m length can produce multiple cabinetry runs, wall panels, door overlays, and furniture wraps.

Custom Branding: Need your client’s logo or a seasonal pattern? Just send a vector file. No need to invest in new molds or tooling.

Enhanced End-User Satisfaction

Performance Guarantees: Most PVC decorative films from reputable suppliers come with 5–7 year warranties against fading, peeling, and cracking.

Ease of Maintenance: A quick swipe with a microfiber cloth and mild detergent restores any fingerprints, spills, or coffee ring drama—key selling point for hotel rooms and retail displays.

Green Credentials

Recycled Content: Team Value offers PCR PET options (20–30% post-consumer content) for clients who want to flaunt sustainability metrics.

Certifications: Our PVC lines meet GREENGUARD Gold for low VOC emissions—ideal for healthcare, schools, and residential interiors where air quality matters.

14. How Team Value Extrudes, Prints & Delivers Quality

Since this article lives on the Team Value website, let’s spotlight how Team Value’s expertise and capabilities ensure you get top-shelf decorative films, every time.

14.1 Manufacturing Expertise

Co-Extrusion Lines: We operate multiple co-extrusion lines with output capacities of 1,000 kg/hr per line. Our rigid PVC lines crank out product widths up to 1.3 m in thicknesses from 0.05 mm to 0.5 mm with tight gauge tolerances (± 0.01 mm).

Biaxial Orientation for PET: Our BOPET lines yield films with a tensile strength of >20,000 PSI and >92% clarity, rigorously tested per ASTM D882. We can do dual-sided anti-scratch and UV coatings to push pencil hardness to 3H–4H.

BOPP Lines for PP: Producing BOPP films in thicknesses from 0.075 mm to 0.25 mm, with integrated corona treatment for better adhesion and printing quality.

14.2 Design & Printing Capabilities

High-Resolution Gravure Printing: Our 8-color gravure presses hit 2,000 LPI (lines per inch), delivering photo-realistic woodgrains, marble veins, and metallic effects.

Custom Texture Embossing: Over 20 unique emboss patterns—woodgrain, stone, metal brushed, fabric textures—achieved via heated rollers with micro-engraved cylinders for deep, realistic textures.

Digital Print & Finishing: Short-run digital printing (up to 60 sqm) for prototyping and sample development. Post-print UV varnishes and matte/gloss topcoats for final finishing.

14.3 Quality Assurance & Testing

Accelerated Weathering: We test PVC films in QUV chambers (ASTM G154) for 2,000 hours to validate UV resistance—no cracking, peeling, or significant color shift allowed.

Adhesion Tests: Cross-hatch adhesion (ASTM D3359) to ensure inks and topcoats bond to the substrate with 5B rating (no flaking).

Fire Retardancy: UL 94 HB or V-0 certifications available on select PVC lines for application in fire code-sensitive projects.

14.4 Logistics & Global Reach

Distribution Centers: Located in Guangzhou (China), Rotterdam (EU), and Los Angeles (USA), enabling 7–14 day door-to-door shipping to most major markets—no more waiting months for product.

Minimum Order Quantities (MOQs): As low as 100 sqm for custom patterns (PET, PVC, PP)—game-changer for smaller B2B runs or pilot projects.

Technical Support & Sample Service: Free e-color cards within 48 hours, physical samples shipped within a week. 24/7 technical hotline for installation guidance, trouble-shooting, and post-sale support.

15. Frequently Asked Questions (FAQs)

Q1: Which film is best for high-moisture environments like bathrooms or kitchens?

Answer: PP or PVC with edge sealers are top choices. PP inherently resists moisture without worry of plasticizer migration, while PVC films with proper edge sealing (using silicone sealants) prevent water ingress. PET could work but may be overkill—and more costly—unless you need ultra-high gloss.

Q2: Can I put PVC film on stainless steel or aluminum panels?

Answer: Absolutely. Use an acrylic-based PSA adhesive or a heat-activated epoxy adhesive to bond PVC to metal. Ensure the metal surface is thoroughly cleaned (IPA wipe) and slightly roughened (light sandblast) for maximum adhesion.

Q3: What’s the difference between monomeric and polymeric PVC?

Answer:

Monomeric PVC: Lower vinyl chloride content (~50–60%), thickness up to ~0.15 mm—budget-friendly but less UV- and heat-resistant (suitable for short-term or indoor use).

Polymeric PVC: Higher vinyl chloride content (~70–80%), thickness 0.15–0.5 mm—better UV stability, less shrinkage, ideal for long-term indoor/outdoor projects.

Q4: How do I know if a film meets fire code?

Answer: Look for UL 94 V-0 or HB ratings on supplier datasheets. If you’re in Europe, check for EN 13501-1 classification (e.g., B-s1, d0 for interior wall coverings). Always ask suppliers for test certificates and data from third-party labs like UL or Intertek.

Q5: Can decorative films be applied over existing wallpaper or paint?

Answer: It’s not recommended. For best adhesion and longevity, strip old wallpaper or loose paint, clean and prime as needed. Films adhere best to smooth, dust-free, solid surfaces.

16. Conclusion & Next Steps

Congratulations—you’ve just unlocked the knowledge vault on PVC, PP, and PET decorative films. We’ve walked through their molecular composition, performance metrics, application arenas, real-world case studies, TCO breakdowns, and installation pointers. We’ve even given you the inside scoop on how Team Value’s manufacturing prowess and logistical muscle can help level up your next project.

Key Takeaways:

PVC – Best all-rounder, cost-effective, endless design possibilities, mid-range durability.

PET – Prime choice for high-end clarity, thermal/chemical resilience, and scratch resistance.

PP – Budget champion, ultra-lightweight, moisture and chemical resistant, ideal for short-term or industrial packaging uses.

Now that you’re armed with the intel, the next move is yours:

Request Samples: Hit up our e-color card service and get digital or physical sample swatches—ask for PCR content if you want that eco-edge.

Design Consultation: Our in-house design wizards can help you trap in your branding or custom pattern ideas—no minimums for up to 5 prototype designs.

Site Visit & Tech Support: Whether you need on-site training for your lamination line or a quick Zoom walk-through of installation best practices, we’ve got your back 24/7.

Ready to roll? Reach out to our sales team, and let’s turn those bland boards, cabinets, or signage into show-stoppers that’ll make your customers say, “Where’d you get that awesome finish?” We’ll be here with popcorn, ready to help you dominate the decorative film game.

Stay awesome, stay creative, and let Team Value’s PVC, PP, and PET decorative films make your next project pop like fireworks at once.