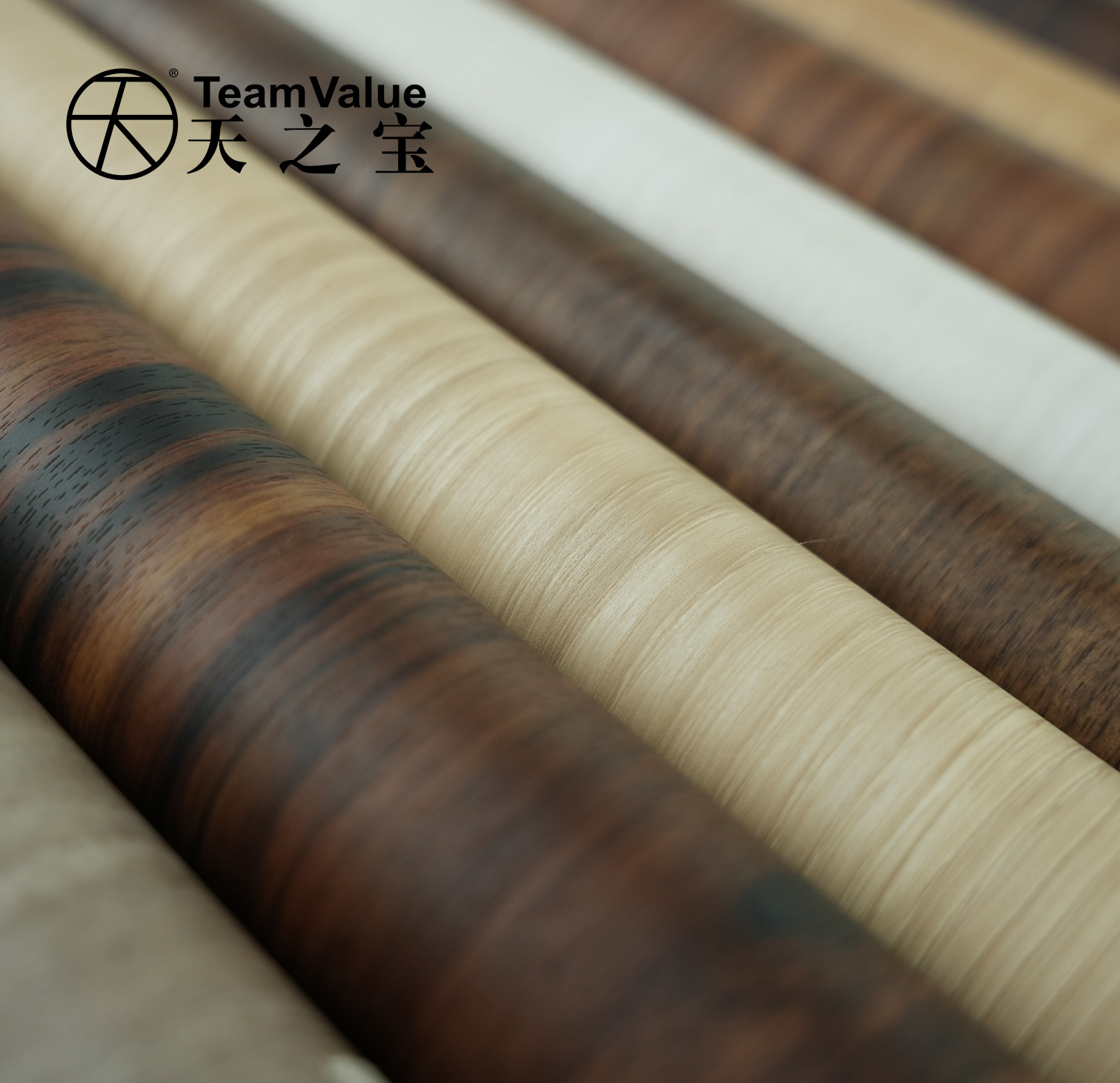

What Are the Key Differences Between PVC, PP, PET, and PETG Films?

When it comes to selecting the right film material for your project, understanding the differences between various thermoplastic options is crucial. Four popular materials—polyvinyl chloride (PVC), polypropylene (PP), polyethylene terephthalate (PET), and glycol-modified polyethylene terephthalate (PETG)—each have unique properties that make them suitable for different applications. Let’s explore these differences.

1. Durability

PVC: Known for its exceptional durability, PVC film resists damage from harsh environmental conditions, including chemicals, abrasion, and impact. This resilience makes it ideal for medium to long-term applications.

PP: Polypropylene is also durable but is particularly known for its resistance to fatigue and stress, making it suitable for applications that require flexibility. However, it may not perform as well as PVC in extreme conditions.

PET: Polyethylene terephthalate is highly durable and exhibits excellent resistance to moisture and chemicals. It is often used in applications where clarity and strength are essential, such as food packaging.

PETG: This glycol-modified version of PET enhances impact resistance and thermal stability. PETG is more flexible than standard PET, making it a preferred choice for applications that require bending or shaping.

2. Safety and Environmental Impact

PVC: While PVC is versatile, it can pose environmental concerns. It is non-toxic when used correctly but can release harmful chemicals when burned. It meets various safety standards, but handlers should take precautions in high-heat environments.

PP: Polypropylene is generally considered safe and environmentally friendly. It is recyclable and does not produce harmful byproducts, making it a popular choice for food packaging and consumer products.

PET: PET is widely recognized for its safety and is commonly used in food and beverage containers. It is fully recyclable and has a lower environmental impact compared to PVC.

![]()

PETG: Similar to PET, PETG is non-toxic and safe for food contact. It is also recyclable, providing an environmentally friendly option for various applications.

3. Fire Resistance

PVC: PVC is inherently fire-resistant due to its high chlorine content. It does not ignite easily and is self-extinguishing, which enhances its safety profile in construction and other applications.

PP: Polypropylene has lower fire resistance compared to PVC and can ignite more easily. It requires careful consideration in applications where fire safety is a concern.

PET: PET has moderate fire resistance but is not as effective as PVC. It can burn when exposed to high temperatures without proper treatment.

PETG: PETG offers improved fire resistance over standard PET, making it a better choice for applications where safety is paramount.

4. Cost-Effectiveness

PVC: PVC is inexpensive to manufacture and easy to shape, making it a cost-effective option for various industrial applications.

PP: Polypropylene is also affordable and offers great value, particularly for applications requiring flexibility and durability.

PET: While PET is slightly more expensive than PVC and PP, its superior clarity and strength often justify the cost in high-quality packaging and other uses.

PETG: PETG tends to be more expensive than both PET and PVC due to its enhanced properties but is often chosen for its versatility and performance in specialized applications.

5. Versatility

PVC: The versatility of PVC allows it to be used in a wide range of applications, including construction, packaging, and medical supplies.

PP: Polypropylene is extensively used in packaging, automotive parts, and textiles due to its flexibility and strength.

PET: PET is favored for beverage containers, food packaging, and textiles because of its clarity and durability.

PETG: With its excellent formability, PETG is ideal for applications that require intricate designs, including medical devices and retail displays.

In conclusion, each film material—PVC, PP, PET, and PETG—offers distinct advantages and is suited for specific applications. Understanding these differences will help you make informed decisions based on your project needs, ensuring optimal performance and safety.