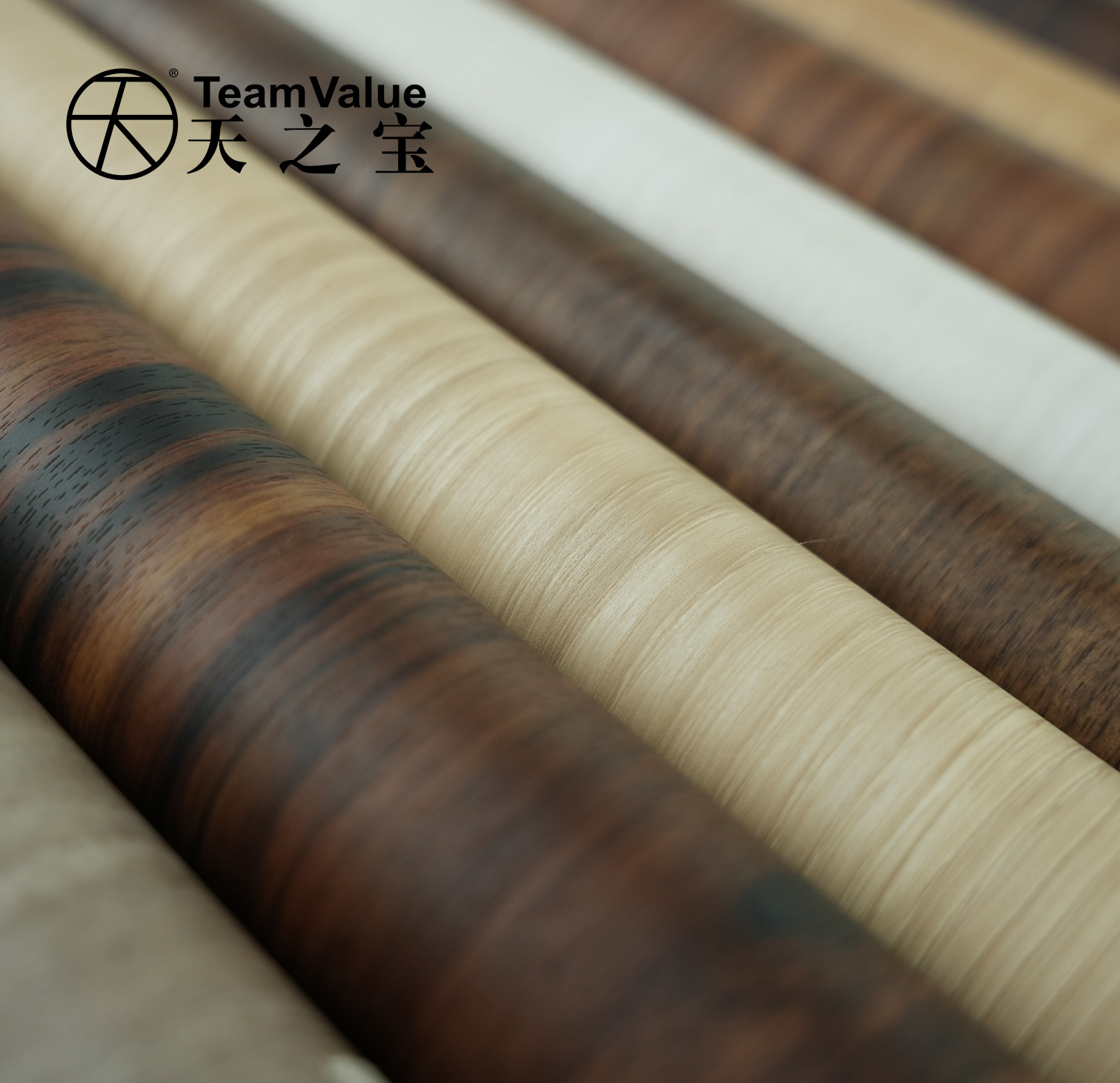

Defining Quality in PVC Film Applications

PVC decorative film is a premier surfacing solution, revolutionizing interiors on furniture, cabinets, walls, doors, and displays with its aesthetic versatility and functional benefits. However, the quality of PVC decorative film varies significantly. Identifying a genuinely good PVC film is paramount for achieving results that are beautiful, durable, and offer true value.

Selecting subpar PVC film leads to disappointment; understanding what makes decorative PVC film 'good' ensures success. This guide dissects the essential attributes defining top-tier PVC decorative film.

The Foundation: What is PVC Decorative Film?

At its core, PVC decorative film is a thin surfacing layer (typically 0.1mm - 0.5mm) manufactured from Polyvinyl Chloride (PVC film) resin through calendaring or extrusion processes. This base PVC film undergoes sophisticated printing, embossing, and coating to produce an immense array of finishes.

A protective wear layer is integral. The final PVC decorative film is laminated onto substrates like MDF, particleboard, or metal using heat, pressure, and adhesives. Choosing the correct PVC film grade is the first critical step.

Defining "Good": Key Attributes of Quality PVC Decorative Film

1. Unmatched Aesthetic Fidelity & Realism

l Print Perfection: Excellent PVC decorative film features ultra-high-resolution printing. The print defines the visual success of the PVC film.

l Embossing Excellence: Superior PVC decorative film utilizes deep, perfectly registered embossing.

2. Exceptional Durability & Wear Resistance

l Abrasion Defense: High-quality PVC decorative film incorporates a durable top coat. Good PVC film bends, not breaks.

l Impact Toughness: The PVC film itself must possess inherent flexibility.

3. High-Performance, Easy-Care Surface

l Stain & Chemical Resistance: Premium PVC decorative film repels common stains.

l Scratch & Mar Resistance: A smooth, hard PVC film surface resists marking.

4. Superior Lightfastness & UV Stability

l UV stability protects your PVC film investment. Formulated with effective UV stabilizers.

5. Robust Thermal Stability

l Stable PVC film handles the heat. Resists lamination temperatures and daily heat exposure.

6. Processing Excellence & Formability

l Post-Forming Capability: Quality PVC decorative film can be thermoformed without cracking. Formability expands the design potential of PVC film.

l Consistent Caliper: Consistency is key for reliable PVC film application.

7. Responsible Composition & Safety Compliance

l Breathe easier with certified PVC film. Complies with indoor air standards (e.g., CARB Phase 2).

l Safe PVC film composition is paramount. Uses non-phthalate plasticizers.

8. Reliable Adhesion

l Strong adhesion is the bond that holds the PVC film surface together. Ensures bubble-free lamination.

The Compelling Case for Quality PVC Decorative Film

Specifying high-grade PVC decorative film yields substantial returns:

l Extended Lifespan: Durable PVC film lasts. Resists wear for years.

l Cost Efficiency: Good PVC film saves money long-term. Avoids premature replacement.

l Brand Enhancement: Quality PVC film elevates brands. Reflects premium craftsmanship.

Final Considerations

A truly good PVC decorative film blends aesthetics with formidable durability.