What is the Difference Between PVC Film and PETG Film?

In the world of decorative surfaces and protective laminates, PVC (Polyvinyl Chloride) film and PETG (Polyethylene Terephthalate Glycol-modified) film are two prominent contributors. While both offer excellent solutions for covering and enhancing surfaces, they possess distinct chemical compositions, properties, and ideal applications. Choosing the right material is crucial for achieving the desired performance, aesthetics, and value. Let's dive into the key differences between PVC and PETG films.

The Core Chemistry: Building Blocks Matter

PVC (Polyvinyl Chloride): Made from vinyl chloride monomers. To make it flexible and workable for film applications, plasticizers (such as phthalates or increasingly, non-phthalate alternatives like DOTP, DINCH, or bio-based options) are added during manufacturing. This addition is key to its flexibility but can influence other properties like long-term stability and environmental perception.

PETG (Polyethylene Terephthalate Glycol-modified): A copolymer of PET (the common plastic used in bottles). The "G" stands for Glycol (typically CHDM - Cyclohexanedimethanol), which replaces some of the ethylene glycol used in standard PET. This modification disrupts the polymer's crystallinity, making it inherently clearer, tougher, and more flexible than standard PET without requiring added plasticizers. It's essentially "plasticizer-free" in its base form.

Key Property Comparison: Strengths and Limitations

Here's a breakdown of how PVC and PETG films typically compare across essential characteristics:

Property | PVC Film | PETG Film | Key Takeaway |

Flexibility & Formability | Excellent. Highly flexible, especially with plasticizers. Easily conforms to complex curves and deep profiles under heat and vacuum. Ideal for vacuum forming over 3D shapes. | Good, but stiffer. More rigid than flexible PVC. Can thermoform, but generally less suitable for very deep draws or complex contours than PVC. May require higher heat. | PVC wins for deep forming. Better for intricate shapes, furniture edges, textured surfaces. |

Clarity & Gloss | Varies. Can range from opaque to translucent. High gloss finishes are common and excellent. Clarity is generally good but not crystal-clear like PETG. Can yellow slightly over very long periods. | Excellent. Naturally very clear and glossy, similar to acrylic. Maintains high clarity over time, resisting yellowing better than PVC. | PETG wins for crystal clarity. Preferred for applications demanding optical clarity (e.g., transparent overlays, high-clarity displays). |

Surface Hardness & Scratch Resistance | Good to Very Good. Surface hardness depends on formulation. Modern PVC films offer very good scratch resistance suitable for most interior applications. | Excellent. Generally harder and more scratch-resistant than standard PVC films due to its inherent rigidity and lack of plasticizers. | PETG often wins on pure hardness/scratch. Better for high-abrasion surfaces or where plastic feel is undesirable. |

Impact Strength & Toughness | Tough & Resilient. Offers good impact resistance and resilience (ability to bounce back from deformation). Resists cracking. | Very Tough & Rigid. Excellent impact resistance (better than acrylic, similar to polycarbonate in some grades). More rigid, less prone to permanent denting than PVC, but can crack under extreme force rather than deform. | PETG is often tougher against impacts, PVC is more resilient. Choice depends on the nature of expected stress (impact vs. deformation). |

Chemical Resistance | Good overall. Resistant to many acids, alkalis, oils, and greases. Resistance depends on plasticizer type. Can be affected by strong solvents. | Excellent. Highly resistant to a wide range of chemicals, including many solvents, alcohols, and oils. Superior chemical resistance compared to PVC. | PETG generally has superior chemical resistance. Critical for labs, medical, or harsh cleaning environments. |

Heat Resistance | Moderate. Typical continuous use temperature around 50-60°C (122-140°F). Can soften or distort at higher temperatures. Plasticizers can migrate at elevated temps over time. | Better. Continuous use temperature typically up to 70-80°C (158-176°F). Less prone to thermal distortion than PVC. No plasticizer migration issues. | PETG offers higher heat resistance. Better for applications near heat sources or requiring higher thermal stability. |

Printing & Embossing | Excellent. Accepts high-quality digital and gravure printing exceptionally well. Ideal for deep, realistic wood grain, stone, and texture embossing. Surface textures are very convincing. | Good, but limited texture. Takes printing very well, especially for vibrant colors. However, it is much harder to achieve deep, tactile embossing like PVC due to its inherent rigidity. Textures tend to be shallower. | PVC is the clear winner for deep embossing & texture realism. Essential for decorative surfaces mimicking natural materials |

Environmental Considerations | Evolving. Traditional concerns around chlorine content and certain plasticizers (phthalates). Modern advancements: Phthalate-free options, bio-based plasticizers, recycled content (rPVC), and dedicated recycling streams are growing. Durability reduces replacement frequency. | Perceived Advantage. Contains no chlorine or phthalates (plasticizer-free). Highly recyclable (often back into PETG streams). Made from common elements (C, H, O). Often preferred in "eco-conscious" branding. | PETG has strong recycling & perception advantages. PVC is advancing rapidly in sustainability (recycled content, non-phthalate). Both have valid sustainability paths depending on formulation and EoL management. |

Cost | Generally Lower. Mature manufacturing process, abundant raw materials. | Generally Higher. More expensive raw materials (CHDM) and processing. | PVC is typically more cost-effective, especially for large-scale decorative applications. |

Where Do They Shine? Ideal Applications

Based on their properties:

PVC Film is Ideal For

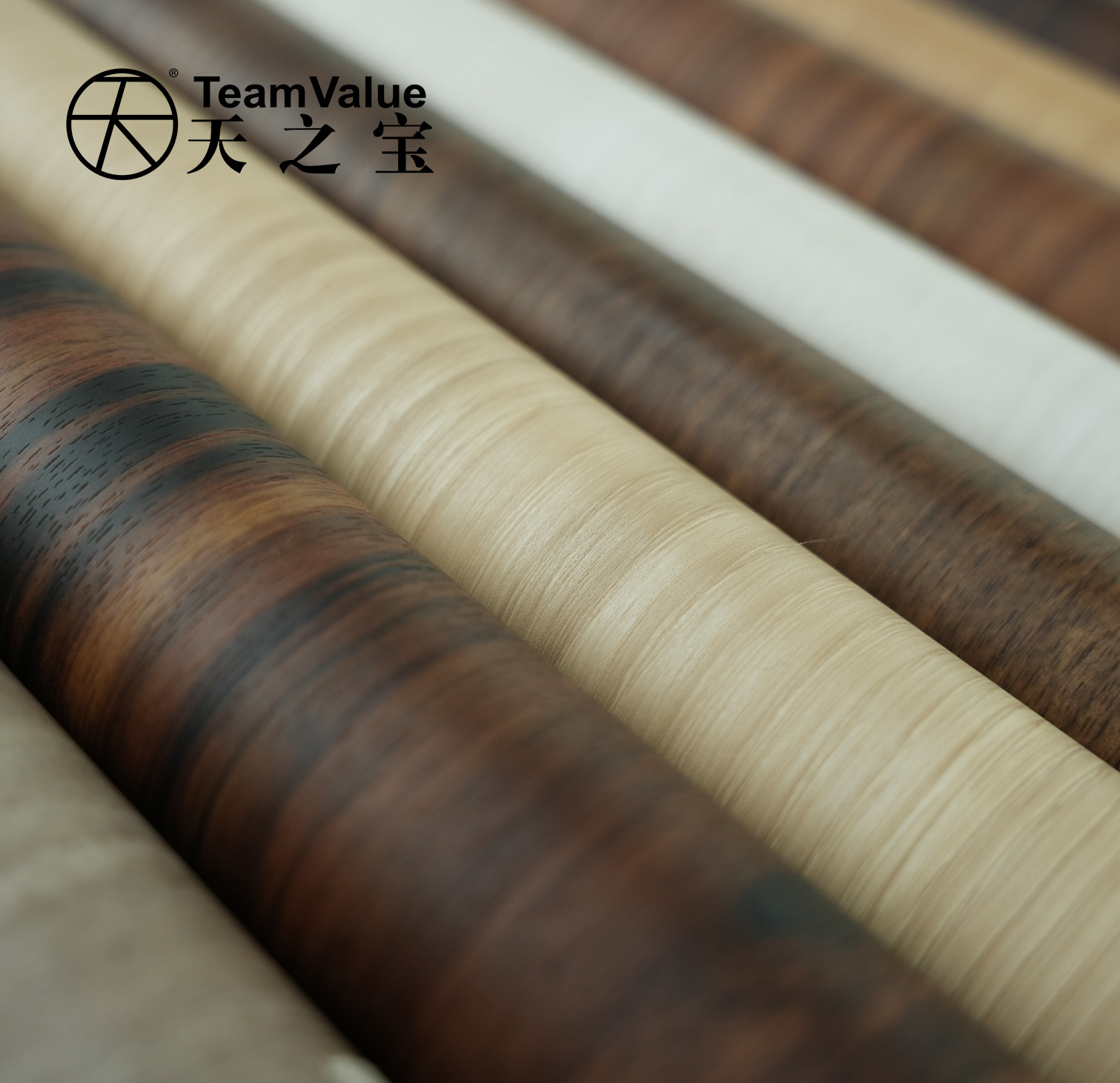

Decorative Surfaces: Furniture fronts (cabinets, wardrobes), wall panels, doors, retail fixtures, automotive interiors. Where deep embossing, realistic textures (wood, stone, fabric), complex forming, and cost-effectiveness are paramount.

Vacuum Forming: Excellent for covering 3D shapes with contours and textures.

Durable Graphics & Signage: Especially where flexibility and conformability are needed.

Healthcare & Hygiene: Phthalate-free, easy-to-clean films for wall protection, furniture.

PETG Film is Ideal For

High-Clarity Applications: Point-of-purchase (POP) displays, protective overlays for menus/signs, machine guards, face shields (non-medical), transparent partitions.

Applications Needing Superior Chemical/Solvent Resistance: Laboratory countertop protection, chemical packaging liners, surfaces exposed to harsh cleaners.

Applications Requiring High Heat Resistance: Near light fixtures, some appliance components.

Rigid Packaging: Blister packs, clamshells (where clarity and toughness are key).

Applications Prioritizing Perceived Sustainability & Recyclability: Consumer-facing products where "plasticizer-free" and "recyclable PET" messaging is strong.

Conclusion: Choosing the Right Film for the Job

PVC and PETG films are both valuable materials, but they serve different purposes optimally. There's no single "best" film; the best choice depends entirely on the specific requirements of your application.

![]() Choose PVC Film when: Your priority is achieving highly realistic decorative textures (deep wood grain, stone), excellent formability over complex 3D shapes, cost-effectiveness for large surfaces, and a balance of good durability and chemical resistance for interior environments. It remains the dominant and highly evolved choice for decorative laminates in furniture, cabinetry, and interior design.

Choose PVC Film when: Your priority is achieving highly realistic decorative textures (deep wood grain, stone), excellent formability over complex 3D shapes, cost-effectiveness for large surfaces, and a balance of good durability and chemical resistance for interior environments. It remains the dominant and highly evolved choice for decorative laminates in furniture, cabinetry, and interior design.

![]() Choose PETG Film when: You need exceptional clarity and gloss, superior chemical/solvent resistance, higher heat resistance, maximum rigidity/scratch resistance, or prioritize the "plasticizer-free" and recyclability perception for specific markets. It excels in protective overlays, high-clarity displays, and demanding technical applications.

Choose PETG Film when: You need exceptional clarity and gloss, superior chemical/solvent resistance, higher heat resistance, maximum rigidity/scratch resistance, or prioritize the "plasticizer-free" and recyclability perception for specific markets. It excels in protective overlays, high-clarity displays, and demanding technical applications.

At Team Value,we specialize in the art and science of high-performance PVC decorative films. We leverage PVC's unparalleled advantages in texture replication, deep embossing, formability, and decorative versatility to create stunning, durable surfaces for furniture, interiors, and beyond. Our commitment to innovation includes developing eco-advanced formulations with non-phthalate plasticizers and recycled content.