Why Does PVC Decorative Film Wrinkle and How to Solve It?

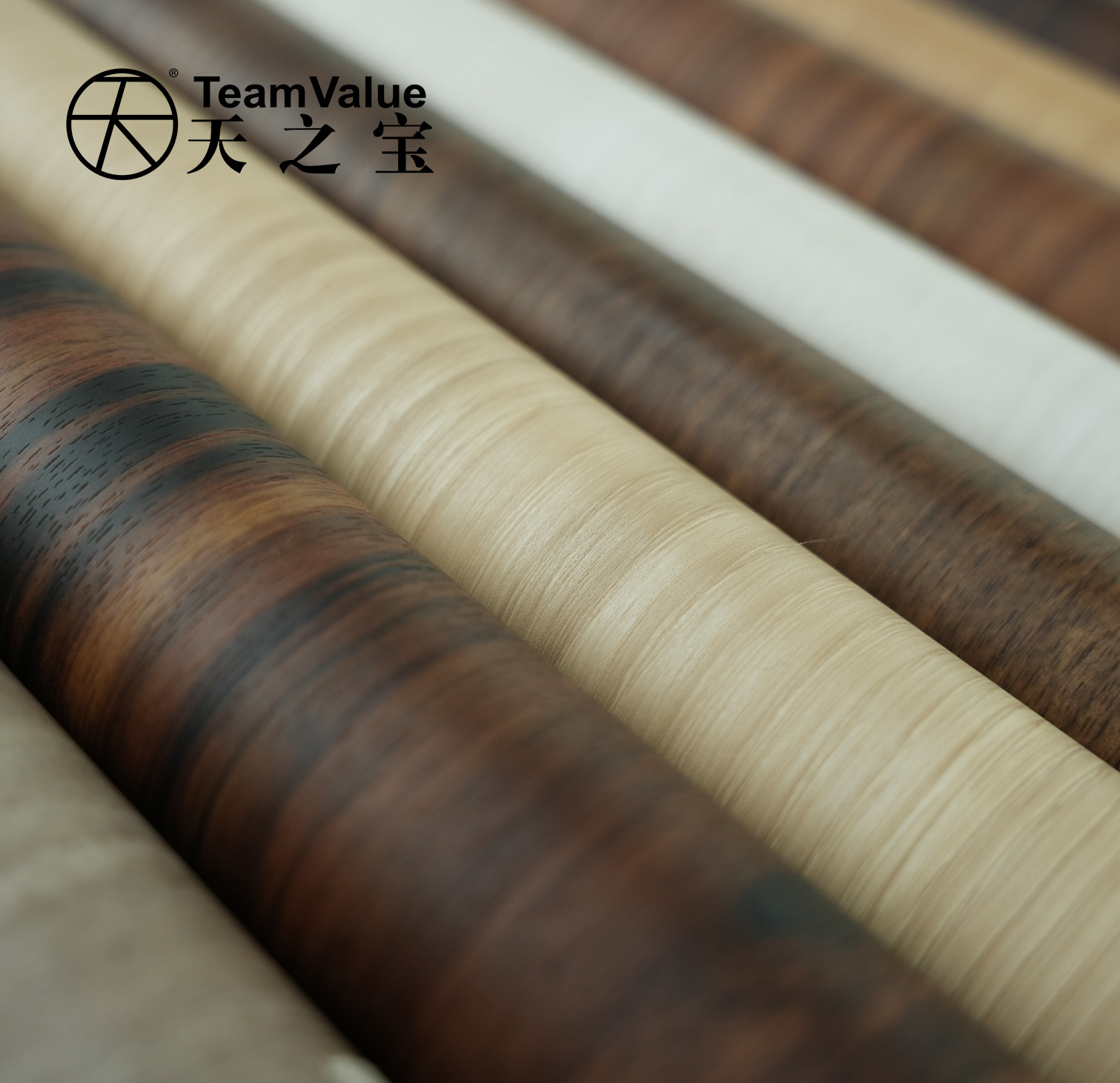

PVC decorative film is a widely used material for surface decoration in homes, offices, and commercial spaces. However, the occasional wrinkling that occurs during the application process can be frustrating. This article delves into the causes of this issue, provides professional solutions, and introduces how TEAM VALUE prevents it at the source.

一、The Three Major Culprits of PVC Film Wrinkling

1.Improper Application Techniques

Substrate Not Cleaned Properly: Dust, oil, or particles on the substrate surface prevent the film from adhering completely, leading to bubbles and wrinkles.

Uneven Glue Application or Wrong Glue Type: Uneven glue spreading, insufficient amount, or using an incompatible adhesive (e.g., one with too high initial tack) makes it impossible to reposition the film, causing immediate wrinkling.

Lack of Skill: Pulling the film directly instead of using a professional squeegee to press from the center outwards, or failing to expel air, creates uneven stress and wrinkles.

2.Environmental and Storage Factors

Drastic Temperature/Humidity Changes: High or low ambient temperature, or high humidity, affects the curing speed of the adhesive and the film's flexibility. The thermal expansion and contraction of the film or substrate can also cause wrinkles later.

Improper Storage: Incorrect stacking of rolls or long-term horizontal storage can cause internal memory deformation in the film roll, leading to natural rolling and wave patterns when unrolled.

3.Inherent Product Quality Issues

Uneven Base Film Thickness: If the thickness tolerance of the PVC base film is poorly controlled during production, thinner areas stretch more than thicker ones, inevitably causing wrinkles due to uneven stress during application.

Internal Stress Release: Lower-quality films accumulate excessive internal stress during production (stretching, calendering). This stress gradually releases after application, causing the film to shrink or expand, forming wrinkles.

Coating or Adhesive Defects: Uneven adhesive coating or incomplete curing results in varying adhesion levels across the film, leading to an uneven application.

二、How to Prevent and Solve Wrinkling?

Prevention and On-site Solutions:

Standardize Application: Ensure the substrate is absolutely clean, flat, and dry. Use high-quality, compatible adhesive and a professional squeegee to press from the center outwards in a "cross" pattern, expelling all air.

Control Environment: Apply under recommended temperature and humidity conditions (typically 15-35°C). Allow materials and adhesive sufficient time to acclimate to the application environment.

Store Correctly: Store rolls upright and avoid heavy pressure on them.

The Fundamental Solution: Choose High-Quality PVC Decorative Film

The best solution is to prevent the problem at the source. Choosing a supplier with strict standards for raw materials, production processes, and quality control is crucial.

三、 TEAM VALUE's Solution: Superior Craftsmanship to Eliminate Wrinkling Worries

At TEAM VALUE, we deeply understand the frustration wrinkling causes. Therefore, we integrate a "zero-defect" application experience into every stage of our product design and production.

1.Premium Raw Materials

We use imported high-end PVC resins and plasticizers to ensure the base film is pure, highly flexible, and consistently stretchable, guaranteeing uniform thickness and stability from the very beginning.

2.Precision Coating and Curing Process

Our advanced precision coating production lines are computer-controlled to ensure every inch of film has a perfectly even adhesive layer. A strict curing process guarantees completely stable adhesive performance, eliminating application issues caused by glue.

3.Superior Base Film Production Technology

Utilizing internationally advanced calendering technology and a fully automatic thickness control system, we ensure our PVC base film has excellent thickness uniformity (tolerance controlled within ±0.02mm). This significantly reduces internal stress and the risk of application wrinkling caused by unevenness.

4.Scientific Packaging and Storage

Our products are packaged on reinforced cores, and we enforce strict vertical storage and transportation rules. This effectively prevents deformation from squeezing, ensuring every roll you receive is in perfect condition.

Choosing TEAM VALUE means you're selecting not just a roll of film, but a promise of a mirror-smooth finish and a worry-free application experience. Contact us today to request a wrinkle-free solution sample!